In manufacturing world, change are sure to happen. It is due to constant improvement in your product design or process modifications. Those adjustments or changes made in product or process plays important role to maintain customer needs and expectations. The Engineering Change Note (ECN) are a systematic and best tool to document and communicate those changes.

In this article we are going to explore what ECN is, it’s importance and How to maintain and implement in your organization.

Let’s dive in…

What is an Engineering Change Note (ECN)?

An Engineering Change Note (ECN) is a documentation done to manage the changes made into engineering designs, product specifications or processes. This ECN process ensures that all stakeholders are aware of the change or modification.

Also, ECN has clear explanation about the reason for change, impact on manufacturing, quality and the end product.

ECN method used in many industry domains, such as automotive, aerospace and other manufacturing sectors. It is one of the key requirement of IATF 16949 : 2016 automotive QMS standard.

During initial development and PPAP submission ECN is the Authorized Engineering Change document.

Important factors of ECN

- Change Description: A detailed explanation of change.

- Reason for Change: Why the change is needed.

- Impact Assessment: How the change impacting our design, cost, timelines, and quality.

- Approval Section: A name and list of authorized persons including customer need to approve the change.

- Implementation Plan: Actionable items including timelines for execute the change.

We will see many more details in below ECN template section.

Why is Engineering Change Note Important?

You already know that ECN is a process to manage changes. There are many reasons for why it is important.

1. Provide Traceability : ECN is a document of clear information on what, why, who and how changes are made. This helps to provide us a traceability of change to communicate in audits, compliances and major failure analysis topics.

2. Better Communication: A detailed change reports gives us a clarity and better understanding of change. It helps to avoid misunderstanding among teams and customer, everyone will be on same understanding.

3. Reduces Errors: The structure of ECN process provides detailed information and step-by-step approach to deal with the change. It helps to minimizes risk of errors in implementation. This process checks all points and approves before mass production.

4. Supports Regulatory Compliance: Industries following strict regulations, for example automotive industries follows standards like IAT 16949 or ISO 9001. ECN is the concept that these standards are more focus on the requirement for change management.

5. Enhances Efficiency: ECN process allow organization to manage change as proposed, reviewed, implement, and approved. This entire process reduces time with improve perfection with cost benefits.

Engineering Change Note (ECN) Process: Step-by-Step

The ECN process have many steps to go through. It is a systematic process. Below are the steps and points taken care by change management.

- Identify the Need for Change

- Prepare ECN document

- Initial review and acceptance

- Communicate the change

- Implement the change

- Validate the change

- Final Status, Approval and close the ECN

1. Identify the Need for Change

The process of ECN starts from need. There is a need for modification or change due to many factors such as Quality issues, customer requirements or request for change, or other innovation related change suggestion.

Identifying those need will initiate the change process within organization, and it is conducted by a change responsible. Many organizations having an engineering department which more likely to responsible to conduct the change process.

Types of Changes Addressed by Engineering Change Note

Following changes are done through ECN processes.

Design Changes

Modification in your design including dimensions, material or any design feature considered as a major change and should be carried out through ECN process.

The design modification can be proposed by customer or internal organizational team considering its impact for good reason.

Process Changes

Change in your process includes manufacturing methods, tooling or fixture modification or change in workflow should be carried out through ECN process.

This is because every modification in your process may impacting product quality, therefore this should be well analyze and then implement using ECN Change management process.

Specification Changes

One specification change we already talk about in terms of design change. But there are many specification which includes technical requirements, standards or performance criteria. Also some points process specification should impacting product.

Those specifications change should be manage properly.

Supplier Changes

Any existing supplier creating problems or our requirement not able to fullfill by them, then our organization looking for new supplier.

New supplier should be analyze and approved. The ECN process helps to analyze and do the risk analysis for new supplier.

Documentation Changes

Revision to documents, manuals, work instructions impacting product and process.

Document Change note helps majority in minor change. But for work instructions, manuals should consider the ECN process.

DCN (Document change note) is a supporting document for ECN process.

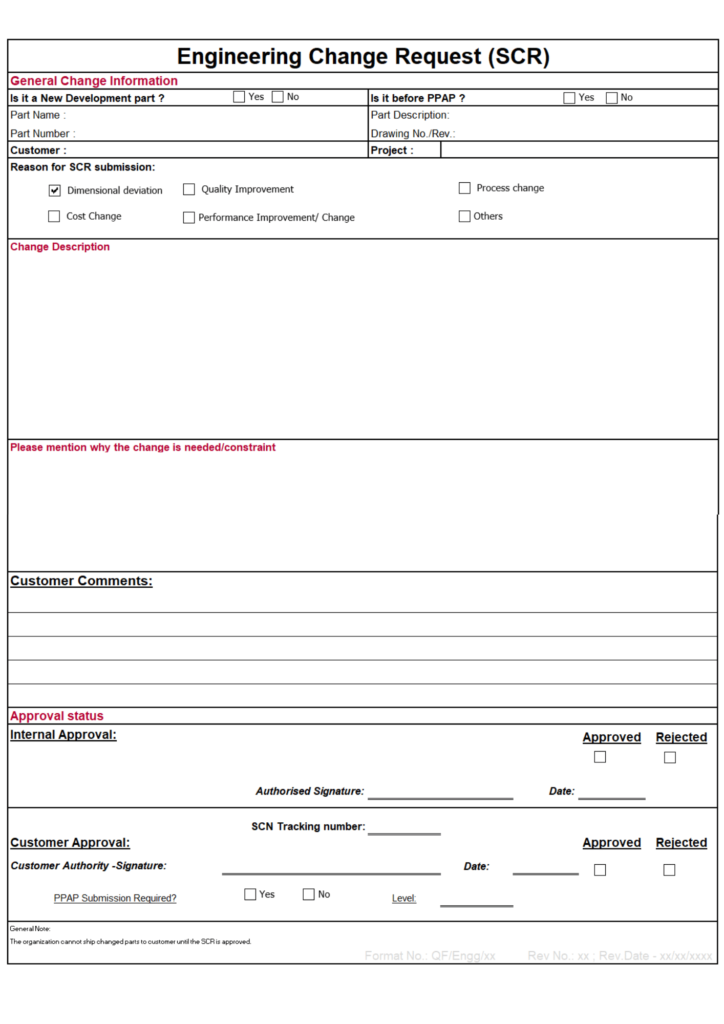

Engineering Change Request (ECR) Form

Now based on above change scenarios, you know what are the changes we can go through ECN process.

Once you find that we have change that should be implemented. You can fill up the form of Engineering Change Request Form.

Change request can be formal or informal. Sometimes E-mail communication is also enough to initiate the change.

Inform or do discussion with responsible or engineering department for the change you request to implement.

Write a mail which includes what is the change description, reason behind the change and who request it. These are basic components of engineering change request.

Once you got acceptance then initiate the change through ECN process.

2. Prepare the Engineering Change Note

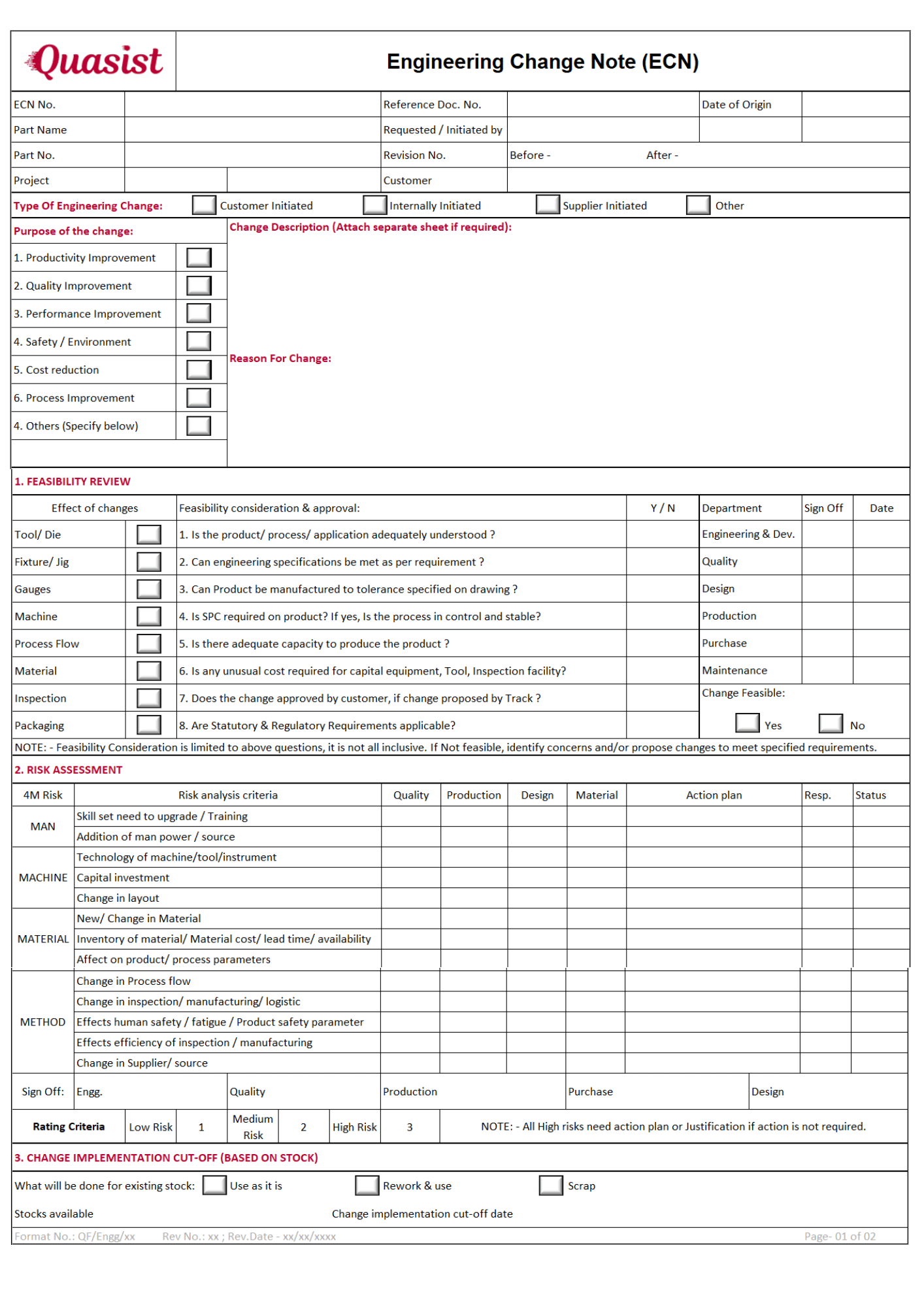

For every change ECN documents need to fill and complete it. Refer below Change note for your reference.

The ECN form includes many points to answer and update it accordingly. Below points should part of ECN document.

How to fill Engineering Change Note (ECN) document

a. Header Section

This section has the basic information such as, ECN Number, initiated date, Product details include customer information, and who initiate this change.

ECN number is the unique identification number provided to change. This ECN number is helping to provide traceability in development cycle.

b. Change Description & Type of Change

Detailed explanation of change. Here you have to write everything about change in shorter description. Sometimes you can attached different sheet to show the change content.

Write a change description in change note and attached separate presentation slide explaining those change in detailed pictures and infographic format.

Select what type of change are you planning. It is either customer, internal or supplier initiated change.

c. Reason for change

Kindly specify your reason for the change.

Some standard reasons are like productivity improvement, quality improvement, customer requirement, cost reduction, and many other.

3. Review and Acceptance

d. feasibility review

It is always better to know the change is feasible or not before its implementation. This section considers the effects of identified change and feasibility studies.

Once team provides the feasibility approval then change enters into risk analysis stage.

e. Risk Assessment

Identifying and analyzing potential risk is the key section of entire ECN process.

In risk assessment you need to analyze 4M (Man, Machin, Material, Method) change conditions and give a specified risk rating to this change.

4. Communicate the change

Share the accepted ECN to all stakeholders, it help everyone is informed about change and their roles and responsibilities.

5. Implement the Change

This step helps to have an implementation plan and monitoring for any potential issues.

f. Change Implementation

When you are going to implement the change, you need to take care of all old stock and inventories.

This is because, once you implement the change there is a chance of mix-up and may impact the customer line stoppage and also facing a traceability issues.

Think about what you are going to do for existing stock? How much stock do you have? And What will be the change implementation cut-off date?

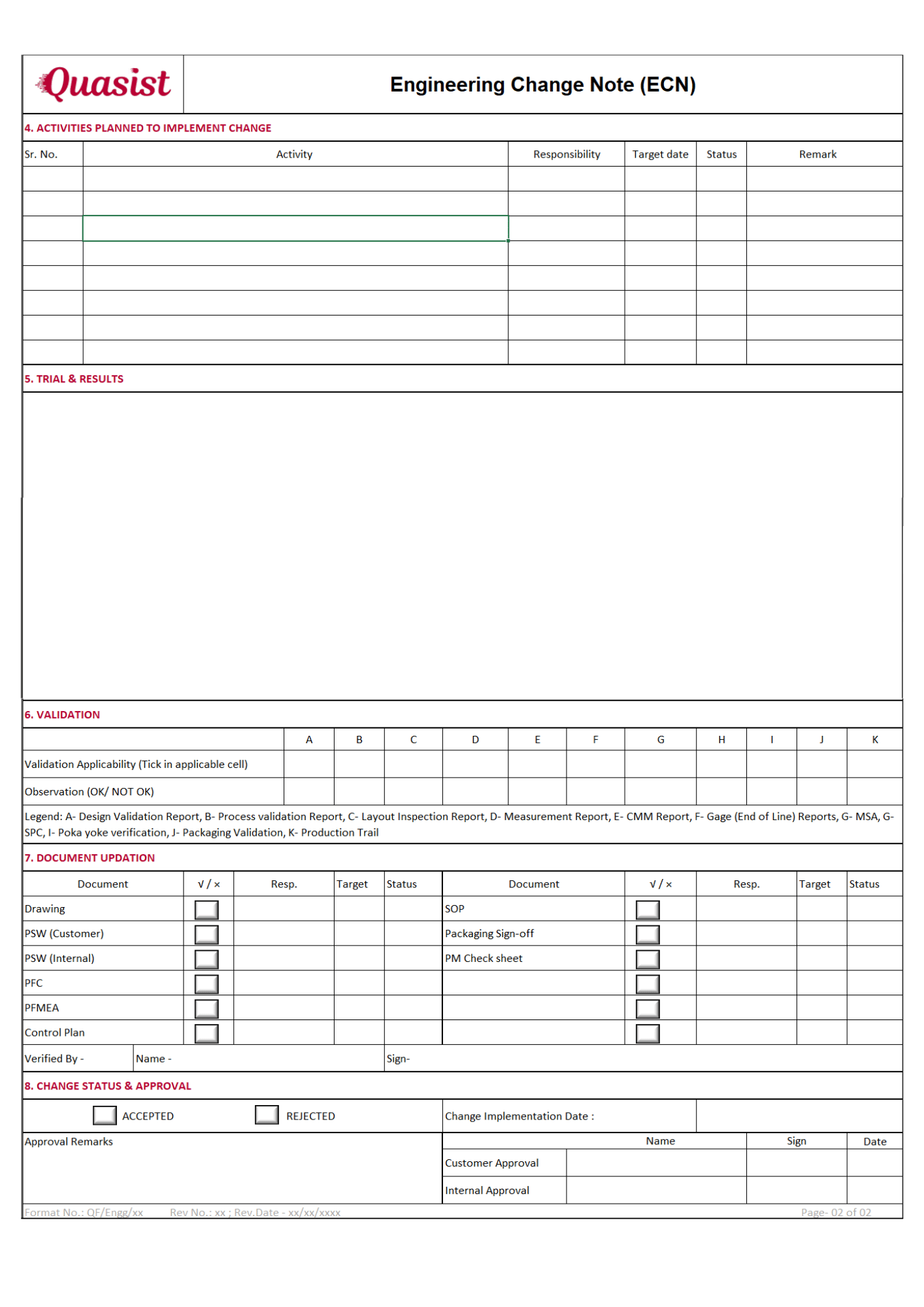

g. Action Plan to implement the change

This sections basically address what are the steps or actions we are going to take to implement the change.

The actions must have a responsible and target date to implement it.

6. Validate and close the ECN

It verifies change has been implemented and these are the results along with documents updates and closing ECN.

e. Validation

Validation is only step where we can say the change is effective or not.

You need to mention that which validation is required for the current change and take all reports of those trails.

Record all trails and results in section as a proof of validation.

f. Document updating

What documents updated or need to update due to this change?

Mention that which documents you are going to update due to this change. The documents can be

- Design / drawing records

- Part Submission Warrant (PSW)

- Process flow chart

- Control Plan

- SOPs

- Design-FMEA

- Process-FMEA

- Etc.

g. Change Status and Approval

Once you complete everything you need to have final approval for this change to have mass production.

The change status includes either project is accepted or rejected with approver remark. Also have information like change implementation date along with approval.

The approval will be internal or customer approval. Depends on change, if it is for internal use then only internal approval is enough. But if the change impacts customer, then customer approval is must.

Download our free ECN template for your change process

Here you are now understand the complete Engineering Change Process.

What are the Challenges in Managing Engineering Change

Engineering change process looks easy but there are challenges too. Let’s understand what are those.

Resistance to Change: Many team members hesitated to accept change. This is because of their perspective like it may create additional workload to them, or the fear of disruption. Many other factors such as organizational condition and corporate politics also major challenge.

Complexity in Large Systems: If your product is more complex, then there are chances of lot of interfaces and interdependent processes involved. Conducting ECN in such complex systems need careful and good co-ordination, therefore it is challenging here.

Documentation Overload: Poor documentation in ECN process leads to have ineffective implementation and creates problems in your product and process.

How to overcome challenges? | Best Practices for Effective ECN Management

Standardize the ECN Process:

Create a clear ECN guidelines and ECN templates to smoothen the change for preparation, change implementation and change approval.

Use Digital Tools | ECN Software:

Take leverage from the software. You can use a software to manage and automate ECNs, which helps effective collaboration among the team.

Engage Cross-Functional Teams:

Cross-Functional team is more important, which involves relevant departments in one evaluation. Departments such as design, quality, production, engineering, etc.

Train Your Team:

Having a good knowledge about ECN processes and change management improves understanding and efficiency. Therefore, provide trainings on ECN procedure and standards are more important.

Monitor and Review

Regular reviews and monitoring current ECNs helps to address and streamline this process.

Conclusion

Engineering Change Note (ECN) is important document to support change management within organization. This change management includes identifying change, prepare for change, do feasibility, includes CFT team to have review and acceptance. Further implement, validate and close the change.

Also organization facing many challenges while transition to changes, but there are many best practices followed by industries to overcome such challenges.

Explore more manufacturing tools and techniques on our blog!

FAQ

An Engineering Change is the modification in our existing product design and processes to improve performance or solved problems in it. These changes may happen due to customer feedback, compliances, cost reduction or other innovation point of view.

ECR (Engineering Change Request): It is a preliminary document submit to propose a potential change. It mentions a change description and reason for change. It doesn’t have any action plan or any other technical details.

ECN (Engineering Change Note): It is a formal document needs to follow or issued after ECR is accepted. It gives the outline of steps for change implementation.

In-short ECR initiate the change and ECN is the final result and track the change.

An example of an Engineering Change could be:

– Change from aluminum to stainless steel for a component to improve durability performance.

– Modify a manufacturing process to meet new environmental regulations.

– Modifying Part dimensions to improve product assembly conditions.

ECN improves manufacturing quality by correcting product and processes, improve consistency, traceability and reducing defects.

An ECN can be initiated by different roles, which is:

– Design Engineers: For product and design related changes.

– Quality Managers: To solve defects or improve product and processes quality.

– Production Teams: To resolve manufacturing issues.

– Customers: Any specific feedback or requirement change related to product.

Depends on change origin it can be initiated by many responsible, but it is always advisable to keep engineering department in loop.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.