Hello,

As I have posted articles on many quality tools, quality engineers are not aware about these concept or don’t know the purpose. So this article explains the must have skills of quality engineer.

After completing your graduation as in Engineering field,

Some of us decide to work in manufacturing industry as a quality engineer.

Then you joined as the fresher in the organization. And as a fresher we need to learn a lot to hold our position in this competitive world.

If you have a good knowledge in manufacturing industry related to your job profile. Then no one have the power to get your position. Even you get the respect from your colleagues. And they will come to you for your guidance or suggestions, so you can help them to come out.

Also you can add these skills in your job portal’s or profile like naukri.

Now for as a quality engineer or fresher, many of us don’t know the exact roadmap for getting trained.

What skills, what knowledge should we have to achieve our goal and grow in your career.

In this post you learn how to identify your skills, how to achieve those skills and how to grow in the career as a quality engineer (Intermediate level or Advanced Level). So that you will be confident in your career and can grab the good opportunity in your career.

Identify your skills

Supplier quality

The supplier quality is related for the quality of buy parts.

The activities include the supplier selection, development, incoming goods inspection, supplier ratings, communication, supplier audits & action plans.

Supplier Selection / Develop : Supplier quality initiate the activity of supplier selection by conducting the audit at various supplier location. Therefore after audit supplier should qualify to the passing criteria. Then the supplier is eligible to supply goods to the company.

Incoming goods inspection : While receiving the incoming goods, inspection is the point where needs supplier quality. Do the inspection as per quality control plan. Measuring instrument handling is the key skills require in inspection.

Therefore measuring Instrument knowledge, instrument calibration and instrument handling are the skills of quality engineer during incoming inspection.

Also the test procedure and perform test if applicable at incoming stage is likely important while inspection.

Supplier rating / Performance monitoring : So monitoring the supplier performance and share the report with supplier needs to be done at define frequency. Therefore record and analyze the supplier data is the key skills quality engineer should have. In that the quality engineer provide the supplier quality rating & customer satisfaction regards to the part history.

Supplier audits : For supply the parts, the company should comply with the requirements of their customer. So that the supplier audit is perform. And at define frequency (As per audit plan) engineer should go to the supplier end and do the audit.

The key skills require here is supplier auditing and give the rating as per audit result. So for that the engineer should have the system knowledge. Therefore In the audit, auditor should capable to verify all finding and evidences in audit.

In Process Quality / Production Quality

The quality engineer is working in in-process quality is more important as compare to other department. Therefore the knowledge of a process quality is important for personal growth.

The key skills require for process quality is,

- Measuring and monitoring the data, In-process inspection.

- Process and product specification,

- Product quality: You should know the customer specific requirement and product specification to achieve product quality.

- Understand & Interpretation of engineering drawing,

- Take countermeasure on nonconformity,

- Instrument calibrations

The process quality plays important role in process control. So every process runs under the process variation. If our process goes wrong or observed in out of specification trend. Then the process quality take countermeasure in process. As a result they bring process within specification limit.

Quality Management System

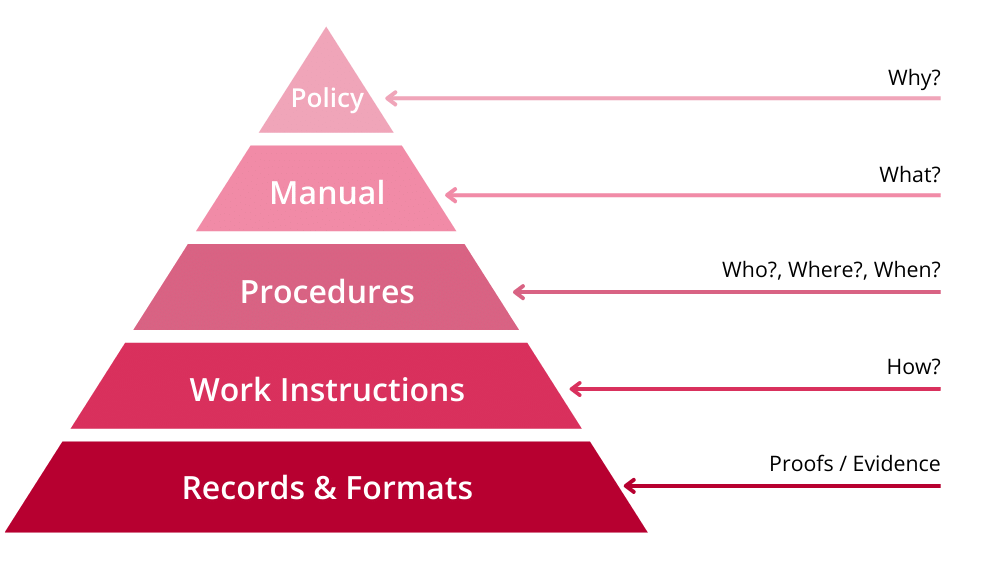

Quality management system is documents processes, procedures, and responsibilities for achieving quality policies and objectives.

In the QMS (Quality management system), engineer should have the knowledge of procedures.

Our KPI’s are link with our organizational goal. Therefore to achieve those goals we need to follow the QMS in our organization. So the key skills for the quality engineer in QMS is having knowledge of listed below points & QMS Formats and Documents.

- Quality Policy

- Quality Manual

- Procedures

- Work Instructions

- Records and formats

Process Capability / Process Improvement

This skills is in demand in manufacturing industry. Lot of rejection and scrap is due to process variation. Therefore we need to maintain our process in capable condition. So the key skills require to achieve capable process is good process knowledge. And skills of reducing the process variation.

Process variation is reduce by process improvement. It can be done by eliminating the special cause variation and reducing the common cause variation. you can learn the common cause and special cause variation in statistical process control (SPC).

Core tools

If you are the master in this 5 core tools, then every company is open for you. In other words these 5 core tools will expand your skills and knowledge in manufacturing industry.

What are those core tools:

- Advance Product Quality Planning (APQP)

- Production Part Approval Process (PPAP)

- Measurement System Analysis (MSA)

- Statistical Process control (SPC)

- Potential Failure Mode Effect and Analysis (FMEA)

I have written a seperate articles on each tool. You can read one by one in detail.

Product quality

Product quality is nothing but to meet customer specifications and requirements. When you achieve all product specification and customer requirement, it means you achieved the product quality.

As a result you need to create the product quality plan.

Do the internal audits.

- Internal Quality Audit (System)

- Process Audit

- Product Audit

- Dock Audit

Likewise you can achieve the product quality.

Data Analysis, Problem Solving & Decision making

To clarify as a quality engineer, we measure data. So that we can identify that the product is Ok or NOK. But finally this is not only purpose of measurement.

We have to analyze those data, and check whether our process is in control or not.

Similarly, if there is problem in the process or product, then we have the problem solving ability to resolve the problem.

In addition a quality engineer must have the decision-making skills.

In conclusion the data analysis is important in problem solving. Therefore on the basis of data you need to take the decisions in respective conditions.

Communication

The quality engineer need to interact with other suppliers / customers and with team members.

Therefore the communication skill is very important. If you communicate well then you got the good response. And you can achieve your organizational and personal KPI.

Effective communication and active listening is essential to teamwork.

Conclusion to Quality Engineer Skills

This is all important skills a quality engineer try to get it as early as in their career. As per experience these skills will refine and strengthen.

More top up of that, lets have a look on the detailed master guide on how you can become a Quality Engineer basic level.