In any circumstances, there is a saying that “Customer is King”. In manufacturing industry your primary objective is to produce parts that meet customer requirement. And Customer Specific Requirements (CSRs) is the key points you need to follow and complete in your initial PPAP submission to get customer approval.

In this article we will have a look on those CRSs in detail.

Let’s dive in….

What Are Customer Specific Requirements (CSRs)?

CSRs are additional requirements by customer, which is not part of our regular PPAP standard.

In PPAP documentation process we have to complete 17-18 documents. But there are additional need and documentation topics ask by customer, those are customer specific requirements.

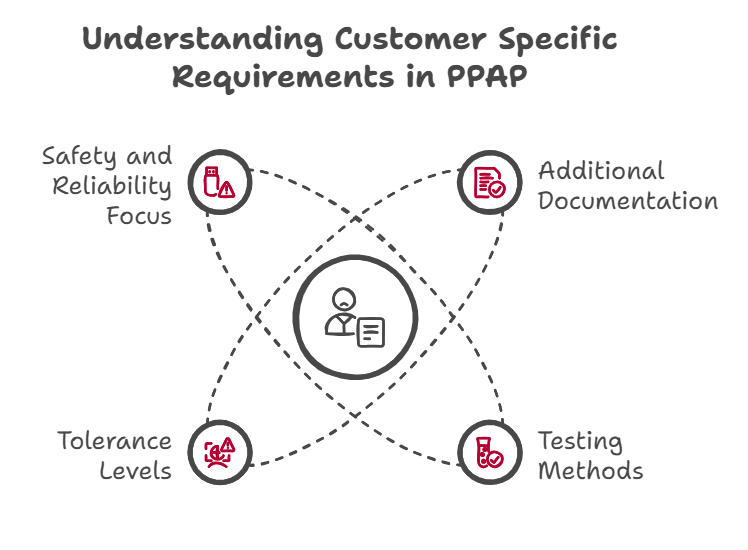

This could be additional documentation, testing methods, some specific format or template needs to fill-out.

Some customers ask you to produced parts with more stringent tolerance, while other customer is more focus on safety and reliability of product. It depends on customer to customer, what they exactly want, and we have to fulfill their expectation through PPAP package documentation.

Now you may have a question,

Where did you find those Customer Specific Requirements?

CSR’s are defined by customer in their supplier manual. Or it can be in your customer development agreement.

Customer contracts is also one of those documents. If nothing is provided, then you have to ask your customer for the same. And still not then its Ok, you have your own PPAP requirements and you just need to align with PPAP standard.

Why CSRs Important in PPAP?

Your PPAP will approved only when you fulfill customer need and expectation.

Therefore to get business and PPAP approval, it is very important to meet customer specific requirements.

CRS helps to have better customer satisfaction, your product meet customer compliances, And avoid the risk of rejection and recall as quality issues from customer.

Common Types of Customer Specific Requirements

CSRs are completely vary customer-to-customer. But still some requirements we have that can be example of this category,

Additional Documentation: Customer may ask you the additional documentation, such as Run-at-rate report, capacity planning and specific work instructions.

Some customer ask you with specific testing, process validation, supply-chain related topics and many more.

It is better that, you walk through customer manual or their PPAP requirements. You will find lot of documentation and other implementation methods that are additional than AIAG PPAP 18 documents.

How to manage CSRs?

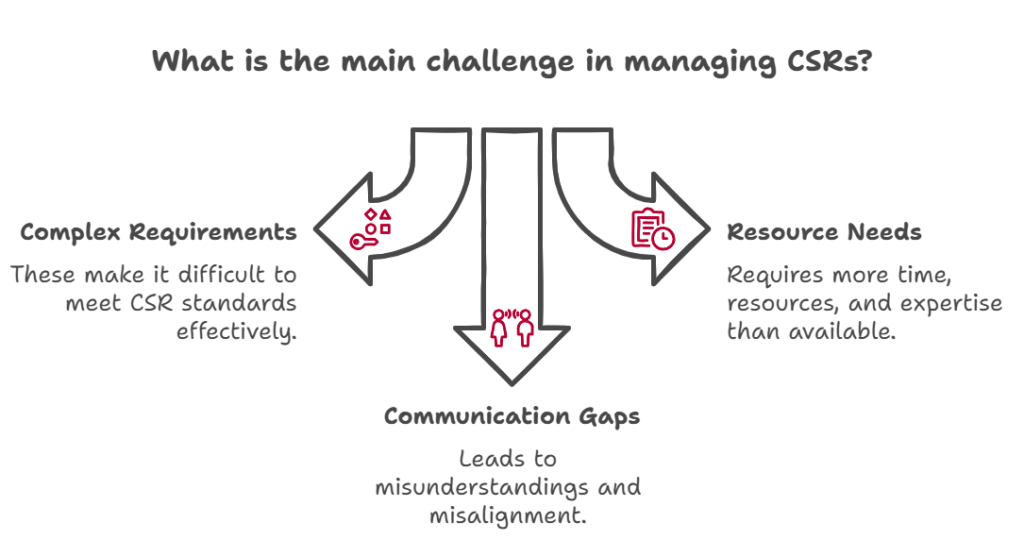

We know CRSs is important, but managing and implementing them is more difficult and challenging. There are reasons for which it is really a challenging to deal with customer specific requirements,

- More Complex requirements

- Additional Time, resources and expertise

- Communication Gaps or misunderstandings

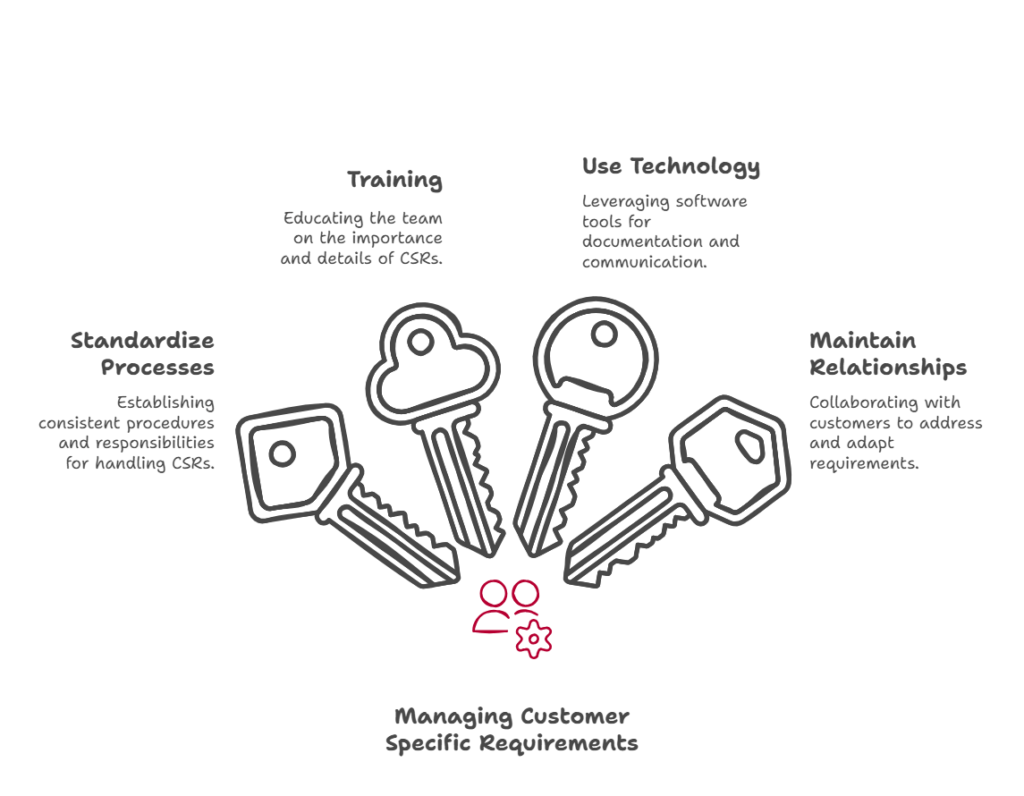

To deal with these challenges we need to focus on the things below,

- Standardize Processes: Create a system to handle the CSRs and development in your project. It can be certain procedures, methods and responsible persons who only take care of customer specific requirements.

- Training: Invest your efforts in training the people. And make sure that your team know the importance and details of CSRs.

- Use Technology: Take leverage of technology like the use of software tools to manage documentation, validations, and communication.

- Maintain Strong Relationships with customer: Work jointly with customer to address issues and their requirement to adapt it.

Summary

Customer-Specific Requirements are a critical topic in your product development and PPAP submission process. By understanding, documenting, and implementing these requirements into your processes, you can ensure customer satisfaction, compliance, and maintain a competitive advantages in manufacturing industry.

Quality Engineer can built strong relation with customer based on fulfilling CSRs.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.