When it’s time to learn the PPAP, and PPAP documents the very first document in the list is Design Record.

To be the expert quality engineer, the core tool knowledge is must.

When we talk about one of the core tool PPAP, it comes to the mind that PPAP is the set of documents.

So, you must know all the documents and hand on experience with those documents.

Here we will discuss about the very first document of PPAP is the design record.

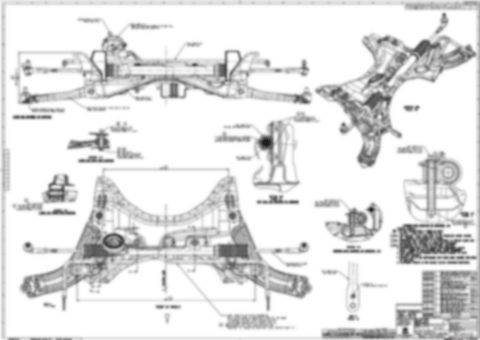

What is Design Record in PPAP?

The details of the saleable part/assembly are the design records. And the details we generally record in the form of drawings or specification sheet.

Therefore the drawings and specification sheets are the design record document in the PPAP.

The design record can be in the form of hard copy or soft copy (electronic format). The hard copy is the design or drawing print on paper containing GD&T Details and all. And the soft copy you can say in the form of CAD/CAM model file in the computer.

Some cases we need to share the design records to the customer. Then you should either share them the soft or hard copy depending on the customer requirement.

The key point to take care of handling design record

- There should be only one design record for the product/part.

- The Design record will be identify using unique identification and revision number.

What if design is not yours?

Many of you are working in Tier-1 or Tier-2 companies. And in such companies the design is not a supplier responsibility.

Then the customer will provide you the design and you just need to manufacture the product to meet the design specification. Provide the manufacturing parts to customer.

In this case take the design record/drawing from the customer and file it in your PPAP documents list.

What if you produce the bulk material or Raw materials?

In this case if particular design is not feasible. Then you should make design record includes the material details, formulation steps or the parameters and final product specification or the acceptance level.

This type of record will helps to identify and qualify your material to the customer.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.