Today we are going to learn about inprocess inspection in detail.

In the manufacturing process, everyone is focusing on product quality. Everyone expects that our manufacturing process should produce the product without defect.

And here, inspection is one of the methods that play a role to detect defects in manufacturing production process.

Now the question is How this type of control helps our manufacturing production process?

Without wasting your time let’s dive in…

What is Inprocess inspection?

When the product/part is in production stage, we need to ensure that all products meet the quality requirements. Therefore In-process Inspection is carried out to ensure that our product batch is ok as per the required parameters and specifications.

There is a simple inspection is done with the help of measurement tools, equipment, gages, and visuals to ensure our product is as per requirement.

What is the frequency of inprocess inspection?

The In-process inspection is carried out at regular intervals. The frequency of inspection could be hourly, once in two hours, two to three times in a shift, etc,

The frequency depends on how could be the variation in process. How we can easily detect defective parts with regular frequency.

Why do we need in-process inspection?

As you know, we do the first part inspection to ensure that our product & process is as per specification and requirement. With the help of FPI our first parts meet the quality requirement.

Now, once the approval is given based on first part inspection, production team then will start production and produce many products in the process. So, due to process variation, material variation and change event in process, there is possibility to producing the Not Ok parts / defective product.

Here in-process inspection is required, to ensure that our entire production batch should meet the quality requirement and free from defective parts.

So, at the regular interval, we will be ensuring our production to be fulfilled the quality requirement.

How to do in-process inspection?

Specifically, this is the inspection activity.

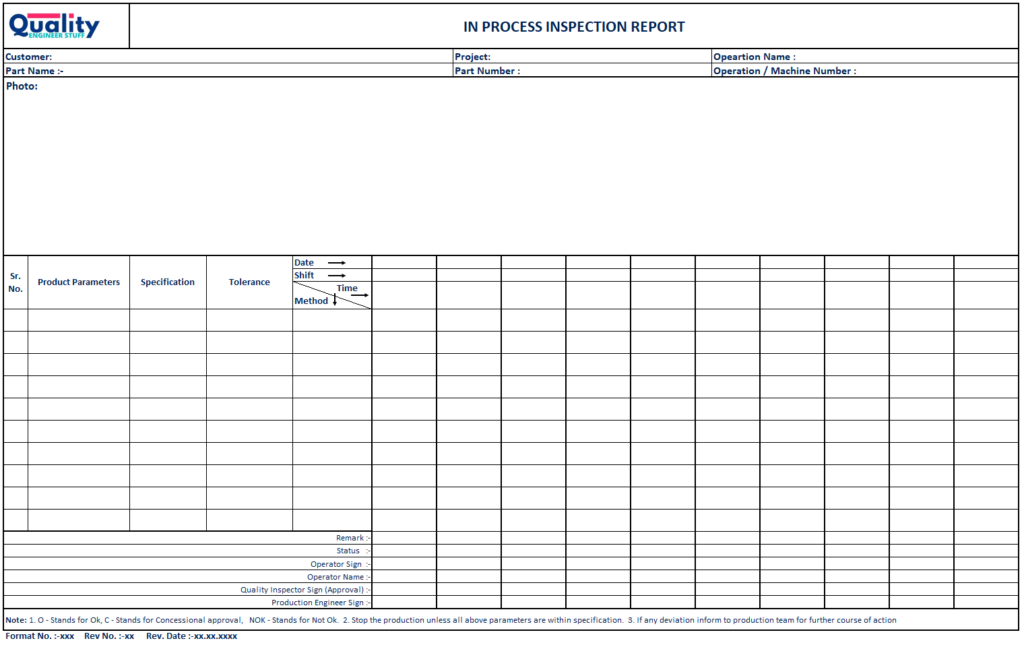

In the control plan, you are going to identify the product characteristics and their control method. Here, inspection report is created based on the control plan.

In the report, product characteristics that we need to check are listed. Along with the parameters how you are going to check this is also mentioned

Finally, the operator should check the product as per inspection methods. That’s it, you need to record inspection results in the report. If you found there is not ok part then you can stop production.

Make corrections, re-check the part after, and then start production again.

Example of inprocess inspection report?

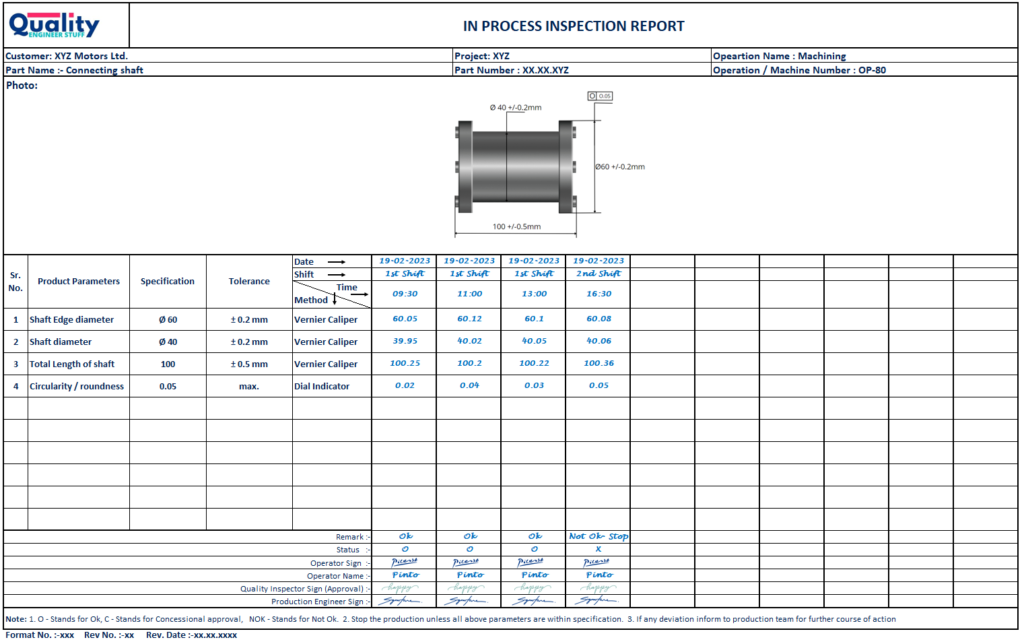

Here is an example of the In-process inspection report. You can easily understand.

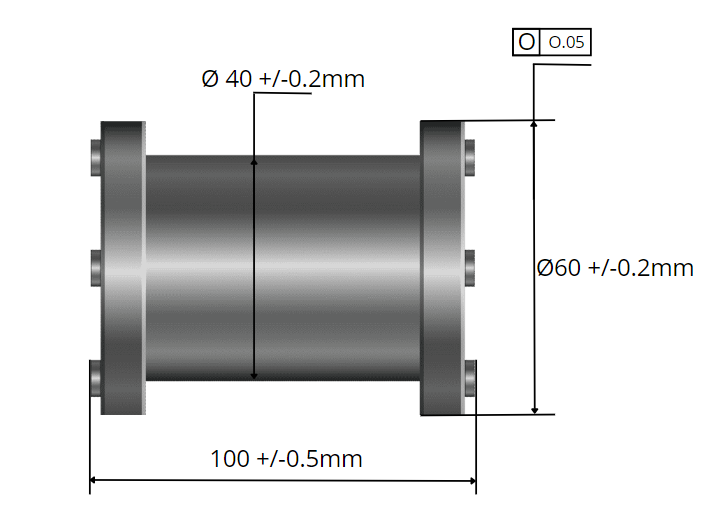

Now we have one product with the product design / drawing as below,

Now we need to add the product characteristics in the inspection report to check in production process,

Refer below inspection report for your reference,

Download in-process inspection report

Requirement of in-process inspection in standard

ISO 9001:2015 and IATF 16949:2016 is a standard for QMS documentation. Which specifically mentions the requirement of “Control of production and service Provision”.

However, it does include a clause (8.5) that requires control of non-conforming output.

So, we need to check our products so that non-conforming parts do not pass to the customer end.

Conclusion

We do the first part inspection to verify that our product and process first part conforms to specification. But after some time if there is any change event happen in process, then there is a risk of defective parts production can happen. Therefore, to avoid cost of rejection and time, we need to perform the In-process inspection. And this is the verification inspection that whatever production we are producing till the time is Ok.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.