Product Audit is mandatory process in every organization. And this article will explain you the detailed guide on product audit in manufacturing quality.

Auditing is important skill in the industry. You can be an expert in quality audit process.

Usually many quality engineers got fear when they heard that there will be an audit.

You can master in the audit skills and can able to face the audit fearlessly by learning and knowing the audit process. You can have a basic look on the audit fundamentals and types of audit for broader view.

We will cover the detailed guide explaining the product audit know how in industry.

What you will learn,

After reading this article you will learn the complete IATF product Audit Procedure and be the expert in product audit concept and can able to perform the product audit by your own.

What is Product Audit?

Product Audit is the auditing process to verify the products are meeting all customer requirements and it’s quality is acceptable for customer use.

Definition of Product Audit

Product audit is a systematic examination of the company’s finished products to check that they meet all customer requirements, quality standards and regulatory requirements.

Product audit is important type of audit in manufacturing industry. As we are making the product through our manufacturing process. And the product is passed throughout the manufacturing stations from incoming raw material to final.

With reference to the product, we need to check that the product is meeting all customer requirement or not. And is there any deviation in our standard operation that there will be high possibility of supplying non-conforming product to the customer.

The Product audit is one of the product verification method but it is different from our regular inspection and verification activity.

Why we do Product Audit?

Manufacturing company has an responsibility to provide the good quality products to the customer. And also the quality engineers are working on to maintain the quality of products as per customer need.

It is essential to have a regular audit to check weather all systems in place. Is our product is handle carefully according to standard or not. Therefore the product audit will help us to identify those gaps and also helps to the manufacturer to improve quality and customer satisfaction.

Also there is a requirement in the QMS standards about the product audit in the automotive industry.

IATF Product Audit requirement

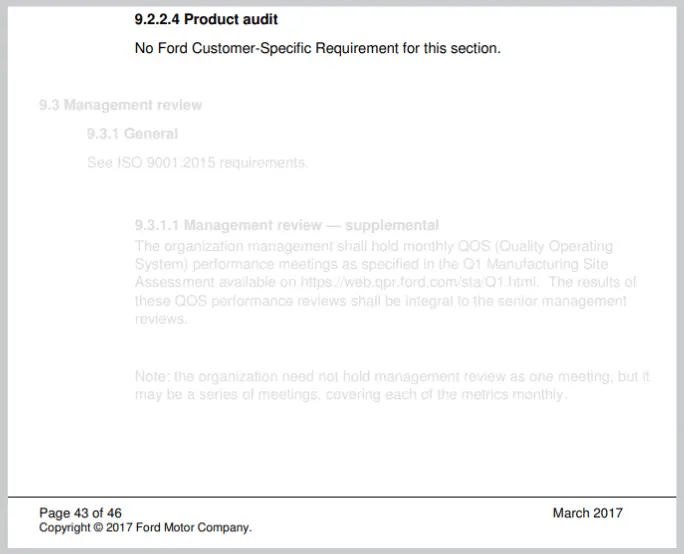

Product Audit IATF requirement is mentioned in Clause 9.2.2.4. What IATF QMS Standard say about Product Audit?

In clause 9.2.2.4 Standard states that “The organization must audit products using customer-specific required approaches at appropriate stages of production and delivery to verify conformity to specified requirements. Where not defined by the customer, the organization shall define the approach to be used.”….IATF 16949:2016.

So the IATF says that the company must do the product audit using customer-specific approach. And if the customer has not defined any approach then the organization must follow their own set of standards or QMS standards to do the audit.

Let’s have a look how you can work on both the approach,

Customer-Specific Approach

This approach is focusing on the customer specific requirement for product audit. Here company should follow the customer guidelines on how to do the product audit and the customer format and reports.

How to follow customer specific product audit approach?

The below steps are usually do to follow the customer specific approach.

- Understand Customer specific Requirement: Each customer has their own set of supplier guidelines and also IATF specific requirements. So go through the product audit requirement of the customer and follow the same guidelines said by the customer.

- Create Product Audit Plan: Create Product Audit plan according to customer define frequency and criteria.

- Perform Product Audit: Based on Audit plan perform the product audit on specific date. Use the customer format and documentation to perform an audit. Write down your findings in the report.

- Customer communication: Make sure that you must communicate the non-conformity related to product to the customer and initiate the corrective action plan to reduce the risk of non-conformity.

- Implement Corrective Action: Implement the actions for the non-conformity.

- Follow-up Audit: Do the follow-up audit to re-verify the non-conformity and once it conforms to the standards and specification then close the Product audit report.

Organization approach

When there is no requirement form the customer or OEM’s on the product audit requirement, then the organization must use there own appraoch to do the product audit.

Refer below requirement from the form motors that there is no Ford Customer specific requirement for this section.

For organization approach on doing the product audit, you can refer the above steps from point 2 to 6 as same. If you want differrent approach you can follow your own organizationsal guidelines.

VDA 6.5 Product Audit requirement

VDA 6.5 Product Audit Manual is followed by German Automotive companies in which all steps and process of conducting the product audit is described. In 2.1.3. What VDA 6.5 manual say about Product Audit?

“A Product Audit is the planning, performance, evaluation and documentation of examinations

(of – quantitative and qualitative characteristics) (on – material product) (after – completion of a production stage)

(and before – It’s forwarding to next customer. Internal/external/next process/sub-sequent process)

(on the basis – of reference values) (through – an independent auditor)….VDA 6.5 Product Audit .

So the VDA says that the company must do the product audit on the production part before its forward to the next station using independent auditor.

When we do Product Audit?

We generally do the product audit based on standard frequency defined and the product audit plan.

Product Audit Frequency

The frequency of product audit is usually done a several times in an year depends on your agreement with customer and risk level of the product.

But many customers do not provide the frequency of product audit. Organization needs to make a product audit plan with defining the frequency of audit based on the product complexity and risk.

How to do Product Audit? | IATF Product Audit Procedure with Example

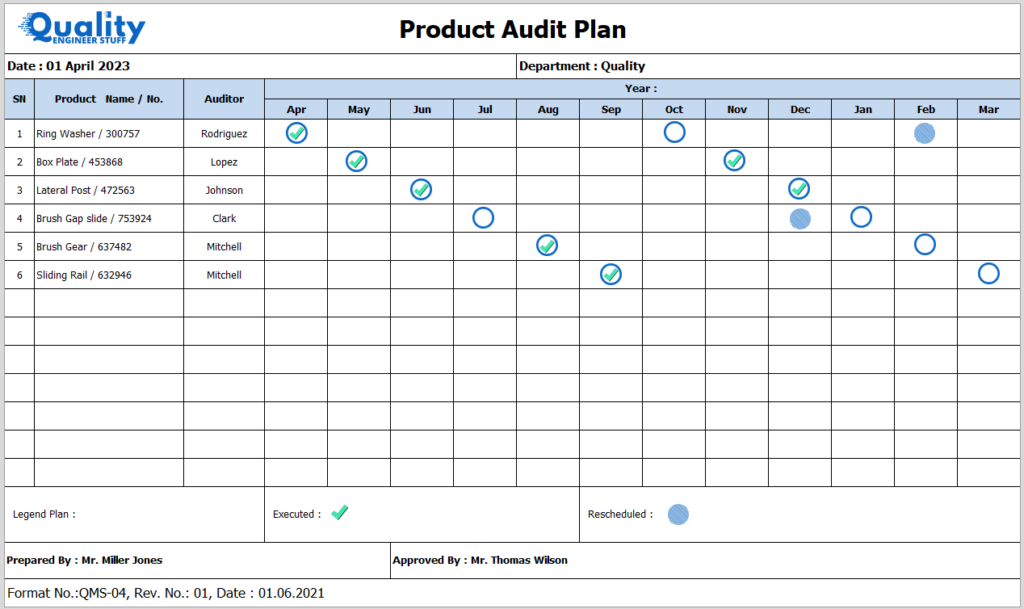

Product Audit Plan

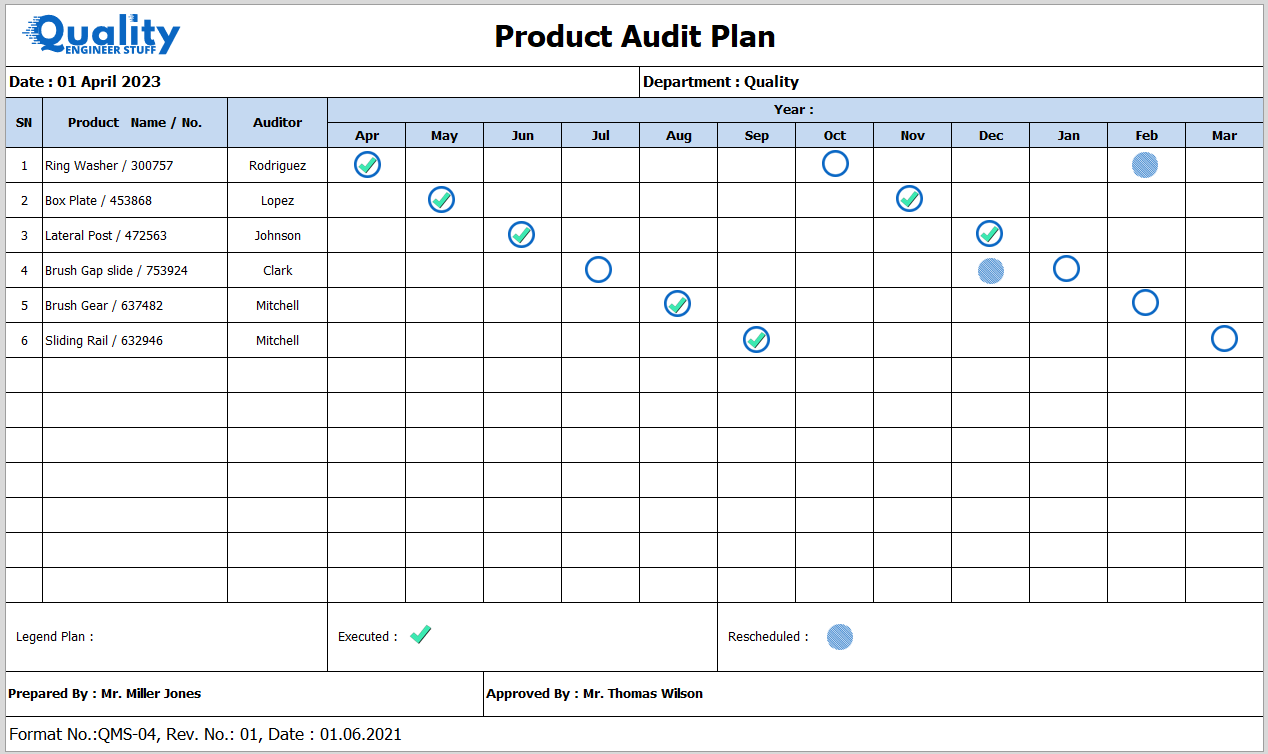

Audit plan is the first preparation document, this will be yearly plan of all product audits with date and who will be the auditor.

Make a product audit plan for the year. In which mentioned the product descriptions, product/part number, Auditor and the product audit frequency.

Refer below Product Audit plan, you can download the product audit plan for your reference.

Conduct Product Audit | Product Audit Report

This is the actual audit execution step.

In which auditor will visit the shop floor or the actual location where the product is been manufactured or assembled. Auditor will do the audit by asking questions and the checklist requirement and auditee will answer and provide the evidences accordingly.

Then auditor will write the appropriate remarks and findings in the product audit report.

Audit Result Documentation

The documentation part of audit consist of the updated product audit plan. Make sure the product audit plan is updated after completion of an audit, mark as completed with respective symbol.

Then the Audit report is the document which has all the product audit findings. The finding could be satisfactory or could be the non-conformity (NC) observed during the audit.

Nonconformities & It’s Type

If you have not fulfill any customer / standard / organization requirement then it means you are not following the guidelines, which is impacting your business system are nothing but the nonconformity.

There are general classification of nonconformity (NC) to Major NC & Minor NC in organization.

The non-conformities (NC) are,

Major NC: The nonconformity of non-fulfillment of customer specific requirement or QMS requirement which impacting your business and system not followed then it will be your major NC. Sometimes violation of legal and regulatory requirements are also a major NC.

Minor NC: The nonconformity of missing or non-fulfillment of requirement which is acceptable at once but further leads to become a major NC are considered as minor NC.

Area for improvement: This is the point suggested by the auditor on any requirement which can be done in better way. Sometimes the industry best practices which helps the business case are considered as area of improvement related remark.

Communicate the audit results

Once you have prepared your result documentation then for further improvement the communication of results including positive and negative (NC) points to the respective department, stakeholder.

Action Plan

To close the NC and improve the product quality an action plan should be provided by the auditee and responsible department. And try to implement those actions for the product.

Follow-up and closure

Auditor can re-verify the improved product to check the effectiveness of actions and follow-up audit for NC points.

Once the results are satisfactory and fulfills the requirements then auditor will close this product audit.

Here your IATF product audit procedure will end.