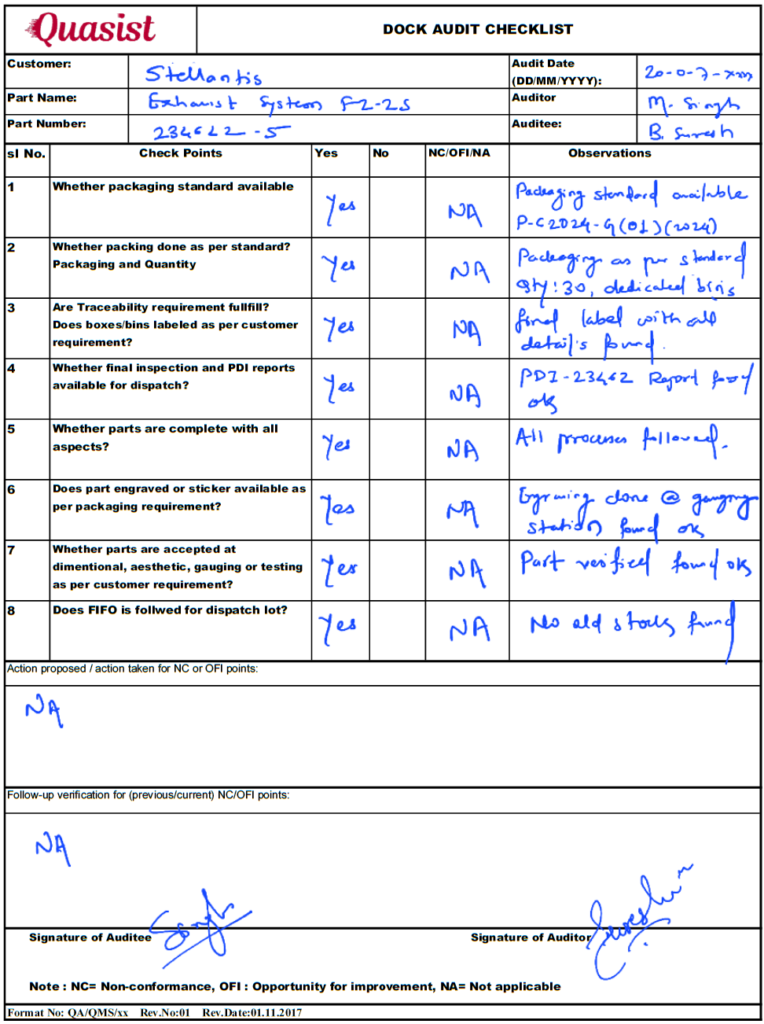

As per Quality Management System, dock audit should be done to check product confirms to customer requirement. It is one of the random inspection process. and done through dock audit checklist.

As a quality engineer you must aware about the dock audit process.

Even in interview several time this topics asked by interviewer.

So, let’s understand the process in detail.

What is Dock Audit?

You know the dock audit is one of the inspection methods but it is done at final packaging station. This means before dispatch of the product.

This method will audit the final packed product visually or the methods as per checklist to confirms that the product is fulfill with customer requirement and does not have any defect in it.

Who perform the dock audit?

Dock audit is performed by quality inspector or quality supervisor, or any dedicated person depend on organizational requirements.

Sometimes due to criticality of product or after major customer complaints Quality Manager may do the dock audit.

Why we do Dock Audit?

The product is gone through many stages in our manufacturing process. Also every stages there are first part inspection done to give product approval for production. Then in-process inspection done in an interval time.

Then final inspection done by quality inspector.

After multiple stage inspection still there are chance of missing some important points which is critical to customer. Those point can be dedicatedly and visually check at dock station before delivery to customer.

Therefore, this dock audit is performed to conform product quality at delivery station.

How to do Dock Audit?

Create Audit Plan

Create dock audit plan or decide the dock audit frequency. This includes the decision of which part and when this audit needs to be done.

Now you may think what is the frequency of dock audit?

There is no such rule to decide the frequency of the audit. Depends on product criticality & customer you choose whatever frequency you want. For example, you can do Dock audit ShiftWise, Daily, weekly, etc.

Dock Audit Checklist / Template

The audit checklist will help to perform audit effectively. Which point exactly need to check on the product and how mentioned in checklist.

This checklist is prepared by considering all customer specific requirements and important points.

For example, in dock audit we usually do inspection of visual defects such as scratches, damages, bend, etc. or sometimes to check the label quality, readability and all. Also some dimensional aspect if necessary to verify at dock yard.

Dock Audit Report / Observation Sheet

Dock audit report is the alignment with checklist so you can write your observation in the report. The report are evidence of performing a dock audit. Sometimes you need to get actual evidence such as pictures or lot traceability number to track a product and check effectiveness of audit.

Corrective Action Report

If you found any non-conformity or defect in the lot/product, then its time to fill corrective action report.

This action report consists of why the defect passed to the next station and how to correct it and prevent it from being happen again in future.