Part Submission Warrant (PSW) is the last document in the list of PPAP.

But PSW will finally decide your PPAP status, either PPAP approved, Rejected or Other. Therefore Part submission Warrant (PSW) is a critical document under the Production Part Approval Process (PPAP).

Every automotive customer will ask you to provide the part submission warrant. And every company is bound to submit to the customer.

Lot of quality engineers struggling to know the PSW and how to fill this document.

This articles will explain you everything about the Part Submission Warrant (PSW). Also you will be master in the PSW document once go through it.

Let’s dive in,

What is Part Submission Warrant?

PSW is the complete summary and coversheet of your PPAP documents and process. The entire information is capture in one document and it will be sign and approved by the customer.

It is a official declaration from supplier that parts meet customer requirements, specification, and production. Then customer sign it to make agreement.

So, you can say that, it is a document sign by customer to provide the approval of production to the supplier on the basis of all details mentioned in Part Submission Warrant document.

- It summarizes the submission.

- Declares that production intent parts were made using production tools, processes, and conditions.

- Acts as a legally binding commitment by the supplier’s quality representative.

Why we do PSW? | What is the purpose of PSW?

Part Submission Documents is the summary of entire PPAP. And the information in the PSW say that we as a supplier meet all customer requirement for the product.

Then the supplier fil the PSW and send to customer. Then customer will verify all PPAP documents and the condition. Signed the PSSW and send back to supplier as a approval.

This means we do the PSW to have a mutual agreement between customer and supplier with accepted condition for the part approval.

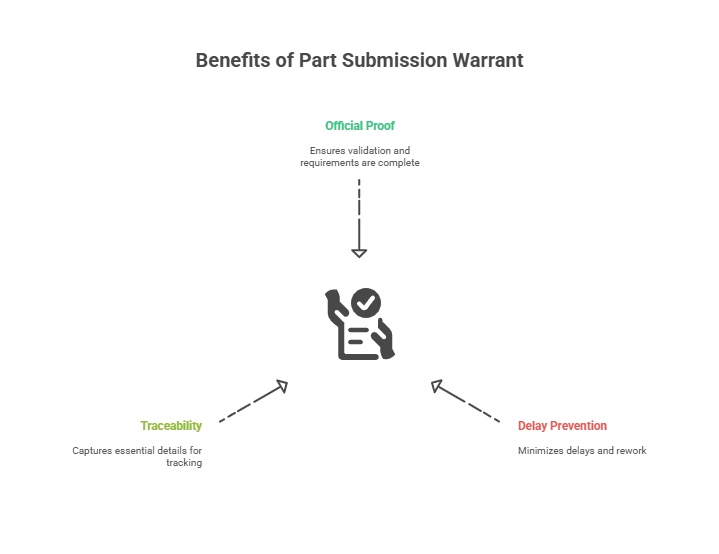

Why is PSW important?

The PSW is important because:

- It is the official proof that all validation and requirements are complete.

- It helps to avoid/minimize delays, rework, or miscommunication between supplier and customer.

- It ensures traceability by capturing essential details like engineering revision, reason for submission, and customer approvals.

👉 Without a properly completed PSW, even a perfect PPAP package can get rejected.

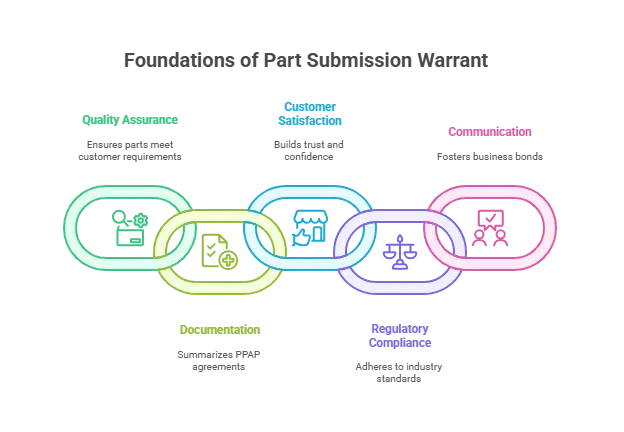

What are the benefits of Part Submission Warrant?

- Quality Assurance: PSW ensures that the supplier parts meets all customer requirement.

- Documentation: It is the important summary document of the PPAP which is signed and agreed by both customer and supplier.

- Customer Satisfaction: PSW helps to build the trust and confidence towards the supplier. It’s because supplier committed to provide best quality parts as per customer requirement to the customer.

- Regulatory compliance: PSW ensures that supplier produce the parts with industry standards and requirement.

- Communication: It is the document which create the bond between customer and supplier in term of business conditions.

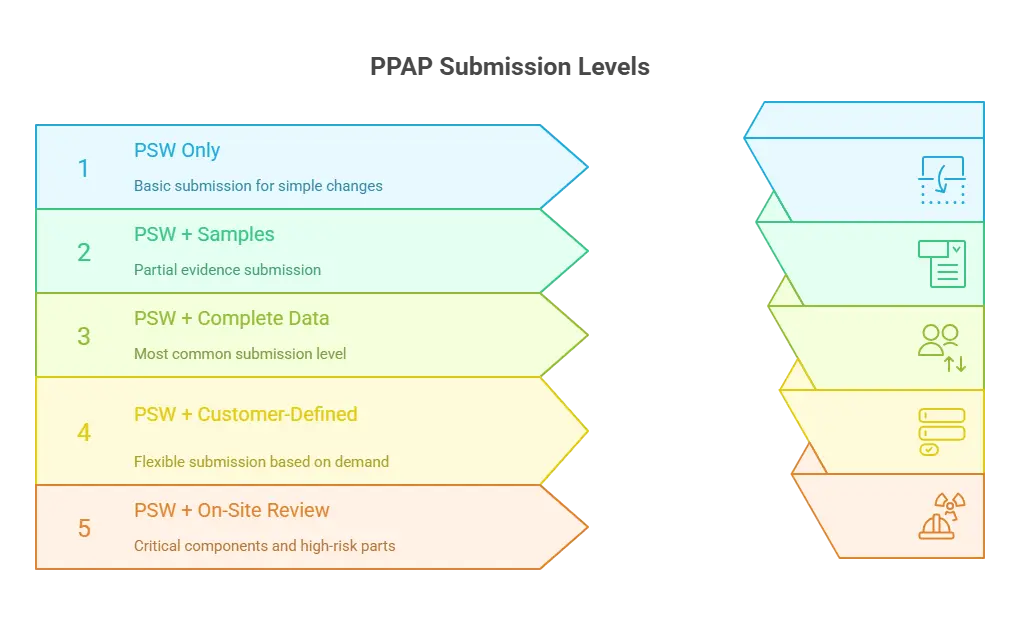

PSW requirement at 5 Levels of PPAP Submission

The PPAP process is divided into five submission levels, depending on customer requirements.

| Level | What is Submitted | When It’s Used |

|---|---|---|

| Level 1 | PSW only (no additional data) | For simple changes or low-risk parts. |

| Level 2 | PSW + samples + limited support data | When partial evidence is enough. |

| Level 3 | PSW + samples + complete supporting data | Most common level required by customers. |

| Level 4 | PSW + other requirements defined by customer | Flexible – depends on customer demand. |

| Level 5 | PSW + samples + complete supporting data + on-site review | For critical components and high-risk parts. |

📌 Tip: Most OEMs prefer Level 3 submissions unless otherwise specified.

Read more: PPAP 5 level of submission and their requirement guide.

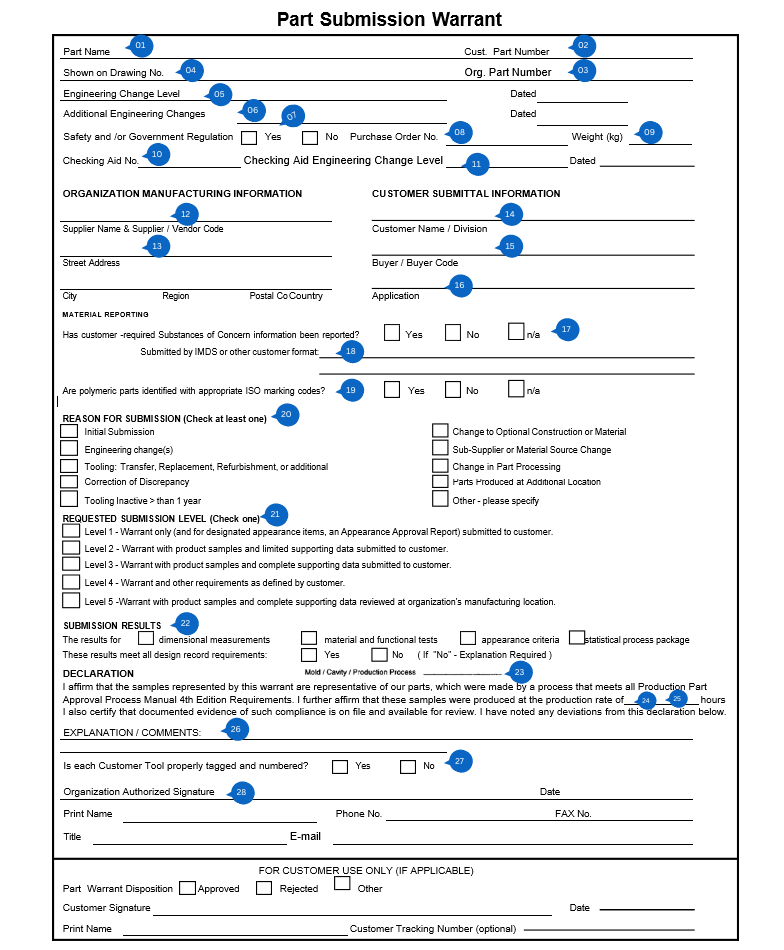

How to make and fill the PSW document?

You can have look on the below complete PSW document.

Let’s elaborate all terms and what information you need to fill there.

Product Details | Part information

- Part Name: Mention the Item part name as per engineering release details

- Customer Part Number: Part number as per Engineering release drawing, or customer communication

- Org. Part Number: Part number what the internal organization is use.

- Shown on Drawing No.: The part number shown on design records.

- Engineering Change Level & Date: Write the updated and latest engineering design change level and date.

- Additional Engineering Charges: Mention all engineering changes which are not available in the design record but those changes are on the part/product.

- Safety and/or Government Regulation: If there any safety and/or regulation then “Yes” otherwise “No”.

- Purchase Order No.: Write the Purchase order number or customer contract number.

- Weight (Kg): The actual weight of the part/product.

- Checking Aid No.: There is agreement as checking aid document in the PPAP list. Write the checking aid number.

- Checking Aid Engineering Change Level: Write the change level and date for the checking Aid.

Organization Manufacturing details

12. Supplier Name & Supplier/Vendor Code: Mention details of the supplier with location and vendor code as per customer contract or customer system.

13. Street Address: Enter exact address of the supplier location.

Customer Information

- Customer Name/Division: Enter customer name and the group/location/division.

- Buyer/Buyer Code: Mention buyer code or name.

- Application: Enter the Vehicle model, engine or type of next assembly, year, etc.

Material Reporting

- Substance of concern information: This field is for the customer requirement on the reporting of material information. If you report the material information then “Yes”, else “No” or “n/a”.

- Submitted by: If you have report the material then, enter how you have report the material. Using IMDS or other customer format. Also enter the date of customer approval.

- Polymeric part identification: If you have a polymeric part the “Yes” or “No” or “n/a”

- Reason for submission: Here you need to tick on one of the reason for which you have submit this Part submission warrant or PPAP.

The PSW or PPAP submission done with one of the below reason.

- Initial Submission

- Engineering Change(s)

- Tooling: Transfer, Replacement, Refurbishment, or additional

- Correction of Discrepancy

- Tooling Inactive > than 1 year

- Changes to Optional Construction or Material

- Supplier or Material Source Change

- Change in Part Processing\Parts Produced at Additional Location

- Other – please specify

- Submission level: When we submit the PSW there are PPAP levels you need to understand. And select one of the level at which you submit the PPAP to the customer. Which depends on the PSW, Product Samples and supporting data.

- Submission results: Tick on appropriate box for the required and submitted results to the customer.

- Mold / Cavity / Production Process: In this field, you should mention about the manufacturing process. If your part is made in more than one cavity or mold or tool then enter the same here.

Declaration

- Samples: Enters the number of parts manufactured during approval.

- Production time: Enter the time at which the above parts are manufactured. This will tell us the production rate at the time of PSW submission.

- Explanation/comments: You can mention additional information, comments which should be added into the PSW as remark consideration.

- Customer tool Tagging/Numbering: If you have a tools provided by the customer, then it should be identified by unique numbering system. Tick mark on “Yes” or “No”.

- Organization Authorized signature: When you filled all above documents then the company authorized person will signed the PSW document. It shows that all customer requirements are meet and mentioned in the PSW document.

Also fill some details of the authorized person, such as E-mail, Contact details, Designation, etc.

Customer Approval Section

- Approval status: Approved / Interim Approval / Rejected

- Customer signature and date

Customer use only fields: These fields should be leave blank. The customer will provide the acceptance and other remark if any.

PSW vs Full PPAP Package

It’s important to differentiate between the PSW and the entire PPAP package:

- PSW = Summary document (cover sheet).

- PPAP = Collection of documents including DFMEA, PFMEA, Control Plan, Dimensional Results, MSA, Capability Studies, and more.

The PSW does not replace PPAP documents. Instead, it references them and provides a formal approval declaration.

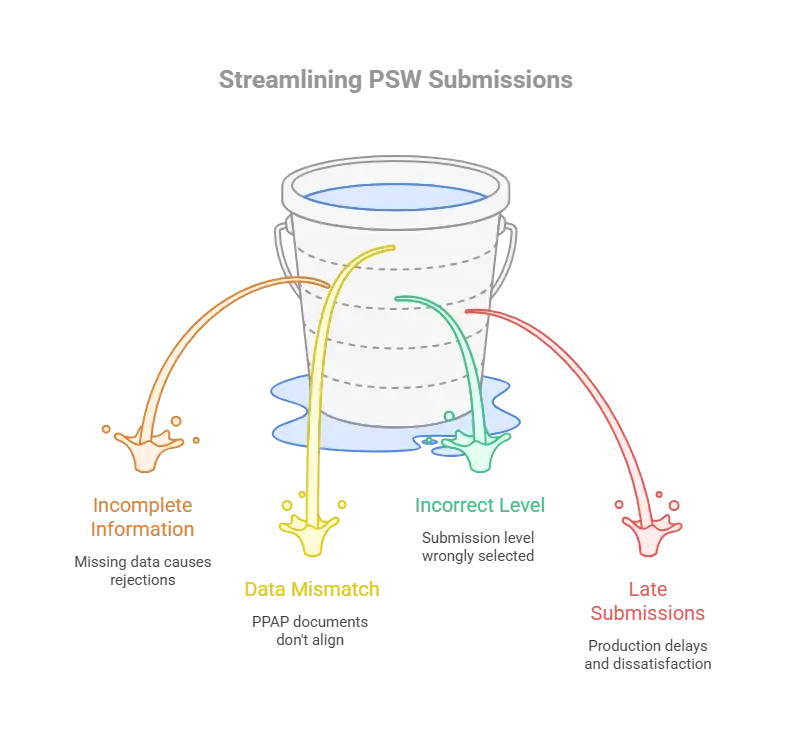

Common Mistakes in PSW Submissions

Many suppliers struggle to fill and submit PSW due to:

- Incomplete information (missing revision levels, unclear submission reason).

- Mismatch between PSW data and supporting PPAP documents.

- Wrong submission level selected.

- Late submissions, leading to production delays and customer disatisfaction.

Best Practice: Always cross-check PSW details with drawings, engineering change notes, and customer requirements before submission.

Best Practices for Quality Engineers in PSW

- Always link PSW data with PPAP documentation.

- Maintain a PSW template library for faster submissions. You can get downloadable PSW template from above downloadable link.

- Review customer-specific requirements (CSR) for PSW before submission.

- Train teams on common rejection reasons to reduce delays.

Conclusion

The Part Submission Warrant (PSW) is more than just a form—it is the final gate for supplier parts goes to customer production. By understanding its requirements, avoiding mistakes, and aligning with PPAP levels, quality engineers and companies can ensure smooth approval and customer confidence.

Frequently Asked Questions

The full form of PSW is Part Submission Warrant. In the manufacturing industry PSW is the agreement document between customer and supplier. Once it is agreed and approved by customer then supplier is capable of doing the business by fulfilling all customer requirements.

1. Level 1 – Part Submission Wrrant (PSW) only

2. Level 2 – PSW, product samples and limited supporting data

3. Level 3 – PSW, product samples and complete supporting data

4. Level 4 – PSW and other requirement define by customer

5. Level 4 – PSW, product samples and complete data reviewed at supplier manufacturing location.

PPAP is the part of APQP process and complete PPAP is signed and approaved by the final submission of PSW documents. Where joint agreement and approaval of production process carried out. It is done at APQP last phse of developement cycle.

A PSW is submitted when:

A new part is introduced.

An engineering change is made.

Production tooling or manufacturing location changes.

Corrective actions require resubmission.

The PSW must be signed by the supplier’s quality representative (or authorized responsible person). On approval, it is signed by the customer representative as well.

Yes. A PSW can be rejected if:

– Required supporting data is missing.

– The submission level does not match customer requirements.

– Engineering revisions are incorrect or incomplete.

– PPAP evidence does not support compliance.

PSW: A single-page summary document confirming compliance.

PPAP: The complete set of supporting documents (FMEAs, Control Plan, Dimensional Results, MSA, Capability Studies, etc.).

👉 The PSW is part of PPAP, but not the whole package.

If a PSW is not approved:

– The supplier cannot ship production parts.

– The issue must be corrected (e.g., update documents, repeat validation).

– Resubmission may be required at the level specified by the customer.

Yes. The AIAG PPAP manual provides a standard PSW form. However, many OEMs also issue their own customer-specific formats. Suppliers should always check the Customer Specific Requirements (CSR) before preparing the PSW.

You can get the latest PSW template from above downlodable link provided on this article. You have a download button for this template in the section “How to make and fill the PSW document?“

PSWs are most common in the automotive industry under IATF 16949 and AIAG PPAP. However, they are also used in aerospace, defense, and medical industries, wherever suppliers must demonstrate part compliance before mass production.