Today is the era of new technology and evolution of manufacturing industries. There is a need of high-quality products that meet customer expectations. Quality engineer is the one who is working from new product development to mass production and maintaining product quality, meet compliances, regulations and customer requirements. Therefore, there is always a huge demand of expert quality engineers, and a skills of quality engineer always make him more suitable for this position.

This article explains all important skills that quality engineers should have, especially for those who are new to quality role.

Many fresh engineers who started as quality engineers in the manufacturing industry may not know which skills to focus on and grow in their careers.

By becoming knowledgeable in your job, you can secure your position, get respect from colleagues, and become a quality expert.

This article a go to resource and provides guidance for you. Also you can add these skills in your job portal’s or profile like naukri.

I have already published lot of articles on manufacturing quality tools and techniques, but many engineers not aware about it.

The skills mentioned in this article helps to get new job and you can also update your resume by updating these skills in it and can grab the good opportunity in your career.

So, what skills, what knowledge you should have to achieve goal and grow in your career.

Technical skills #

1. Core tools Skill (Very Important) #

Quality engineers need to be experts in core quality tools such as,

- APQP (Advanced Product Quality Planning)

- PPAP (Production Part Approval Process)

- FMEA (Failure Mode and Effects Analysis)

- MSA (Measurement System Analysis)

- SPC (Statistical Process Control)

- Control Plan (CP)

These core tools help to manage your product and process quality from initial development to ongoing mass production.

APQP gives us the quality planning approach to do the new product development as a first-time right approach. PPAP is the approval process focused on documentation package.

FMEA helps to do product and process risk analysis by identifying future failures and how to avoid them by a proper prevention and detection controls.

MSA make sure that your measurement systems are good enough to capture accurate data. Whereas SPC helps to monitor and check your process behavior.

If you are the master in these 6 core tools, then every company is open for you. In other words, these quality core tools will expand your skills and knowledge in manufacturing industry.

I have written a separate article on each tool. You can read one by one in detail.

2. Quality Functions (On-the-job skills) #

You must know all these skills to survive in your quality job.

Because these skills helps in your day-to-day work and challenges. Those are divided into departments and

a. Supplier quality Skills #

The supplier quality is related to quality of purchased parts from supplier/vendor.

Here, the tasks of supplier quality are supplier selection, development, incoming goods inspection, supplier ratings, supplier communication, supplier audits & action plans.

Supplier Selection / Development : Purchase team find out the best supplier in market then supplier quality will perform the audit to check whether this supplier is capable to produced and provide parts or not. Therefore it is the first activity of supplier selection by conducting the audit at various supplier location. After audit supplier should qualify to the passing criteria and then the supplier is eligible to supply parts to the company.

Incoming goods inspection: When parts received from supplier, it need verification. Supplier incoming quality team will check all incoming parts and then provide approval to pass those parts on manufacturing line. Do inspection as per quality control plan. Therefore, from skill point of view handling measuring instrument is the key skills require here.

Quality engineer must have measuring Instrument knowledge, instrument calibration and instrument handling during incoming inspection. Some cases test procedures and perform tests is required, this is also important to know.

Supplier rating / Performance monitoring: Supplier rating and monitoring the supplier performance is key topic in supplier management activity. Supplier quality engineer is responsible to monitor supplier performance and share the report to supplier at define frequency (most cases it should be monthly). Therefore, record and analyze the supplier data is the key skills quality engineer should have. Quality engineer will provide rating to supplier based on monitoring data.

Supplier audits: Supplier should consistently produced good quality parts. For that supplier quality team will do a regular supplier audits to check their system and compliances. Supplier quality engineer will be the responsible to do a supplier audit at defined frequency. It could be once in a year as per supplier audit plan.

The key skill is auditing. Quality engineer should give proper ratings based on audit findings and give a final score and audit results.

b. In Process Quality / Production Quality skill #

Process/Production quality engineer is important person. Therefore this skill is always a demanding. Production quality engineer have complete knowledge about product and process.

He can be the master of process as well. Because here production is done, where produced good quality parts. Those parts check by quality person and if there is problem in that then quality engineer will take a part and do correction in process with the help of operator or process expert.

The key skills require for process quality is,

- Measuring and monitoring the data, In-process inspection.

- Process and product specification,

- Product quality: You should know the customer specific requirement and product specification to achieve product quality.

- Understand & Interpretation of engineering drawing,

- Take countermeasure on nonconformity,

- Instrument calibrations

The process quality plays important role in process control. Every process runs under the process variation. If our process goes wrong or observed in out of specification trend. Then the process quality take countermeasure in process. As a result, they bring process within specification limit.

c. Quality Management System Documentation Skill #

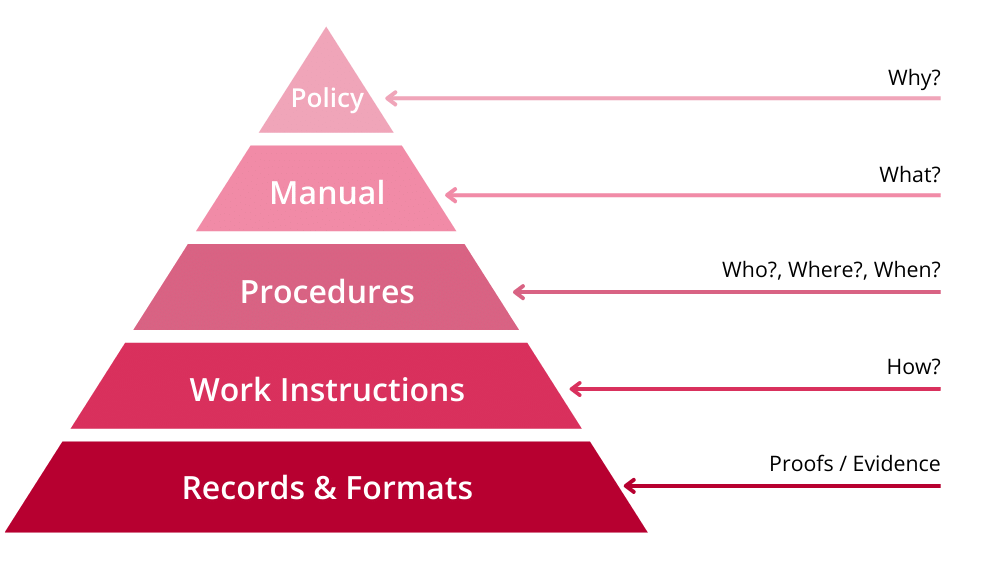

Quality management system is a combination of quality manual, quality policy, work instructions, procedures and records. It is done to achieved your organizational goals and objectives.

In simple words, it is a documentation methods where everything is mapped and track to monitor and perform our company processes.

QMS documentation is key skill that every quality engineer should have.

QMS engineer basically it is a quality engineer who do this activity in organization.

Let me explain you the QMS in short.

We defined our company goals into Quality Policy, then we create our Quality Manual on how our organizational processes are align as per QMS standard. Now we create Procedures to explain who, where and when those processes are. Then we create work instruction on How to perform those processes and all these data stored in your records and formats.

- Quality Policy

- Quality Manual

- Procedures

- Work Instructions

- Records and formats

So, the key skills for the quality engineer in QMS is having knowledge of listed below points & QMS Formats and Documents.

d. Process Capability / Process Improvement Skill #

This skill is in demand in manufacturing industry. Companies facing lot of rejection and scrap due to process variation. To avoid rejections, we need to maintain our process in capable condition. So, the key skills require to achieve capable process is good process knowledge and skills of reducing the process variation.

Process variation is reduced by making process improvement. It can be done by removing the special cause variation and reducing the common cause variation. you can learn the common cause and special cause variation in statistical process control (SPC).

e. Product quality #

Quality department is always work on to check product quality and focusses on providing good quality products to customer.

Product quality is nothing but to meet customer specifications and requirements. When you achieve all product specification and customer requirement, it means you achieved the product quality.

As a result, you need to create the product quality plan.

Do the internal audits.

- Internal Quality Audit (System)

- Process Audit

- Product Audit

- Dock Audit

Audits are the verification methods to check whether your product, process and system are in placed to produced good quality products consistently or not.

3. Data Analysis, Problem Solving & Decision making #

As a line inspector, he measures a data and record it in inspection reports or sometimes in control charts. This activity is done to check the part is OK or NOK. But unfortunately this is not a final purpose of measurement.

As a quality engineer you should analyze this measurement data over the period of time and find out whether your process is in control or not.

The ability to analyze data and draw a meaningful conclusion is important. Quality engineers should use statistical methods, including control charts, SPC capability indices to do this type of analysis.

As a result if you know that your process are not in control, then make a correction in process and bring this in control.

But you may have a question that how do I correct the process?

Here, the skill of problem solving is helping you.

Knowledge of below problem-solving methods can able to find out root causes effectively.

- 7QC tools.

- 8D methodology

- six sigma

- QC story method

And you can do improvement by taking actions on root cause.

In addition a quality engineer must have the decision-making skills. You should take a decision of making correction with the help of data. This sows you take a authority and accountability of your job. It will help you to build your reputation in your company.

In conclusion the data analysis is important in problem solving. And on the basis of data you need to take the decisions in respective conditions.

4. Software Proficiency #

Most manufacturing companies are now transitioning into digital ecosystems. For that they use specific software’s to manage their processes.

Manufacturing companies uses a software’s such as,

- Quality Management Software

- Project Management Software

- Risk Analysis Software (Such as FMEA Software)

Therefore, now-a-days every quality engineer must have a competency in quality management software. FMEA Tools such as Apis IQ RM, Knowlence TDC, and Plato SCIO do a efficient FMEA creation, analysis, and documentation.

Engineers familiar with these tools and techniques can help organization to ensure compliance with industry standards such as IATF 16949 and ISO 9001.

Emerging Skills in manufacturing Industry #

1. Industry 4.0 Technologies #

Industry 4.0 completely transforms manufacturing domain. In the era of industry 4.0, new technology are now adopted by manufacturing companies, which includes smart manufacturing concepts, such as IoT based quality inspection and monitoring, predictive analysis, AI based visual inspection and digital technological tools.

Quality engineer should try to understand these tools to grow in their career. These technologies basically improves quality control processes in real time measurement and monitoring data.

2. Functional Safety Expertise #

Now if you are working in Automotive Electrical / Electronics system manufacturing industry, then it is mandatory to compliance with functional safety standard. As a quality engineer, expertise in ISO 26262 and IEC 61508 standard is valuable.

3. Lean and Six Sigma Certification #

Certification in lean manufacturing or lean six-sigma methodologies are highly valuable. There are many certifications out there, such as Green Belt, Black belt certifications.

The knowledge of these methodology helps quality engineer to solve problems, improved their processes and can eliminate defects or waste.

Soft Skills for Career Growth #

1. Communication and Leadership #

A good communication is must for every quality engineer.

Quality engineer is the one who interact with customer, supplier, cross-functional team, therefore he must be good in communications.

The communication skill is very important. If you communicate well then you got the good response. And you can achieve your organizational and personal goal easily.

Additionally, leadership skill are also important because you are working with team who creates many documentations, such as FMEA, control plan and reporting. So, you need to guide the team for correct approach, here your leadership skill matters most.

2. Project Management #

Many times, quality engineers manage departmental or complaint related projects, which involves cross functional team. Skills in planning, resource allocation, and timeline management are essential to successfully deliver projects with maintaining quality.

3. Problem-Solving Mindset #

Problem-solving is always in quality engineer’s blood. Quality engineer should be expert to solve issues such as rejection, customer complaint, improvement, cost savings and many more.

The process to solve problem is like identify problem, find out root cause, take corrective action, prevent reoccurrence of problem.

Career Growth Tips #

1. Pursue Relevant Certifications #

Having below certifications provide you the credibility and expertise in your field.

- ISO 9001 Internal Auditor / Lead Auditor,

- IATF 16949 Internal / Lead auditor

- Six Sigma Green Belt / Black Belt

- CQE (Certified Quality Engineer) by ASQ

These qualifications open many doors like advanced roles and increased in your job responsibilities which again help to grow in your career.

2. Build a Professional Network #

Have a networking with industry peoples through forums, conferences, and social media platforms (LinkedIn / Facebook). That helps quality engineers stay updated on trends and got insights of best practices and new technologies. Engaging with the quality community increase knowledge sharing and career growth.

3. Commit to Lifelong Learning #

The field of quality engineering is big and dynamic. Quality professionals should continuously update their skills through latest articles, online courses, webinars, and industry publications.

Staying connected with emerging technologies and methodologies provide long-term success.

Conclusion to Quality Engineer Skills #

In 2025, quality engineers should combine their technical skill with emerging industry knowledge and soft skills to grow in their careers. By mastering core tools, new technologies, and committing to continuous learning, they can become a good assets in the manufacturing domain.

Take the first step today by exploring resources and opportunities available on Quality Engineer Stuff to build a career in quality engineering. More top up of that, lets have a look on the detailed master guide on how you can become a Quality Engineer.