Let’s learn today, the topic of IMDS in PPAP.

When you try to learn the PPAP or create the PPAP for the program. Then the IMDS requirement is there. You should aware about this requirement.

From customer point of view IMDS is key data system, And every supplier should follow it.

This article will tell you exactly what is the IMDS requirement mention in PPAP manual.

What is IMDS?

The full form of IMDS is International Material Data System.

In the automotive industry, one online website platform is available for IMDS. And this is generally the database for all the OEMs.

So, the IMDS is the big database system, where all suppliers are put there components material details to fulfill the OEMs requirement regards to ELV directives.

The ELV stands for End-of-Life Vehicle. And this directives says that your part should not have restricted chemical elements, such as cadmium, hexavalent chromium, lead, and mercury.

Also the IMDS helps OEM to track down the materials of vehicle for their recycle conditions and calculation.

Each individual OEM has their different requirements for the materials, therefor check with your customer.

What is IMDS in PPAP?

You are now aware that the IMDS is the international material data system. And the OEM asks supplier to mentioned their requirements in the IMDS portal.

Next OEM will give you IMDS approval if its meet the OEM requirement. Further the OEM will track down all components material condition for their recycle or calculation purpose.

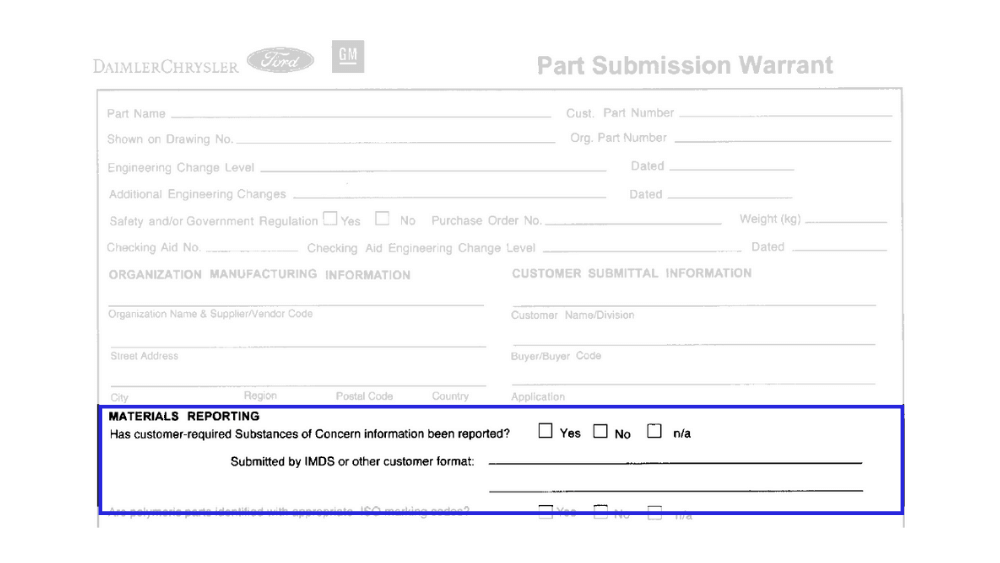

Now in latest PPAP 4th edition, The IMDS requirement is mentioned directly in the PSW document.

It means supplier should mention the status of the IMDS approval in the PSW.

How you fulfill PPAP IMDS requirement?

In the IMDS portal, a unique supplier code provided for each supplier.

Now he can update their components and material details in it.

Then the customer will provide the approval on the same, if it complies to the requirement.

Once you got the approval, you can use the same information and update the PSW documents as IMDS “Yes” and update the details.

IMDS Chain

In database a complete chain of material information maintain. For example, your sub-supplier update the data for his components. This data is submit to you.

Then you update you component and submit those data to your customer. Then your customer will provide you the approval on complete data.

This is very mature and best system for reporting the materials to the customer.