In manufacturing industry, it is important to produce parts that meet customer requirements. The requirements are in the form of dimensional, functional and regulatory. But visual appearance is also important requirement that contributes major factor in part quality.

Therefore, Appearance Approval Report (AAR) plays important role to get aesthetic approval from customer during initial development Production Part Approval Process (PPAP).

In this article, we are going to learn everything about AAR reports and its fundamentals. Once you understand it then you will have expertise of one of the PPAP documents.

What is an Appearance Approval Report (AAR)? #

The AAR is one of the PPAP document which confirm that all parts visual and aesthetics characteristics align with customer requirements. It is similar to dimensional report, here we add all aesthetic points jointly aligned and approved with customer.

Most of time it is mandatory to the parts visible to end user. For example, in automotive industry, lot of parts are visible in car such as interiors, exterior, electronic devices casings or consumer products.

AAR reports addresses many visual factors, such as color, surface finish, texture, gloss level, and other decorative elements. These all points should meet design specifications and approved with customer using signed Appearance Approval Report as a PPAP documentation package.

What is the purpose of AAR report? | Importance of AAR in PPAP #

There are 4 major purpose to create AAR report:

- Defect Prevention: It identifies and highlight potential appearance / visual defect early in development phase before doing mass production. Once got approval from customer then we probably prevent future failures using AAR report.

- Future misunderstanding: In coming future your product or part may degrade in appearance. Or customer demands something different that what you agreed. In both condition your old appearance approval report will help you to again stand on same page. And customer will also agree that yest what was earlier approved the same condition is now present in your product.

- Customer Satisfaction: Obviously, if you prepare a appearance approval report which shows that your part meets all customer visual requirements leads to improve customer satisfaction and trust.

- Regulatory Compliance: Appearance standardization and approval process meet the industry-specific appearance standards or guidelines. Which again a good sign that your company is the best quality parts manufacturer.

There are 3 reasons why the AAR is important, by submitting the Appearance Approval Report document into PPAP, manufacturers can:

- Reduce risks of customer dissatisfaction.

- Avoid costly rework or rejection in mass production stages.

- Create strong trust and collaboration with customers.

When Appearance Approval Report Required? #

Now you know how important AAR report is but when it is required?

The AAR is required in following conditions:

- During new product or part development.

- If change in raw material, process or supplier that affect product appearance in this case AAR approval required.

- Change or modification in existing tooling or molds.

- Design or part change request by customer. As a customer request there is a need for AAR submission.

The Process of Appearance Approval #

The formal process to create and approved AAR reports includes below steps,

- Preparation

- Sample

- Inspection

- Documentation

- Submission

- Feedback and approval

Let’s understand each steps in details.

AAR Preparation: Review all customer requirements and specifications in aesthetics relation. Includes related standards and customer documents.

AAR Samples: Collect and provide samples to do the appearance inspection from production sample or PPAP samples.

Inspection: Do the thorough inspection of samples for all specified points. Consider other aspects of visual inspection workstation such as lux level and measurement are cleanliness to avoid any defects or wrong results.

AAR documentation: After inspection record and document all your findings in appearance report. This report includes all relevant results and photographs for future concerns.

Submission: submit the results as AAR document to customer for approval in your PPAP package.

Feedback and Approval: If customer agrees and AAR report meets his expectation then he will simply approve and give you the appearance approval.

Once you got the approval along with PSW approval you can able to do mass production and eligible to provide parts to customer.

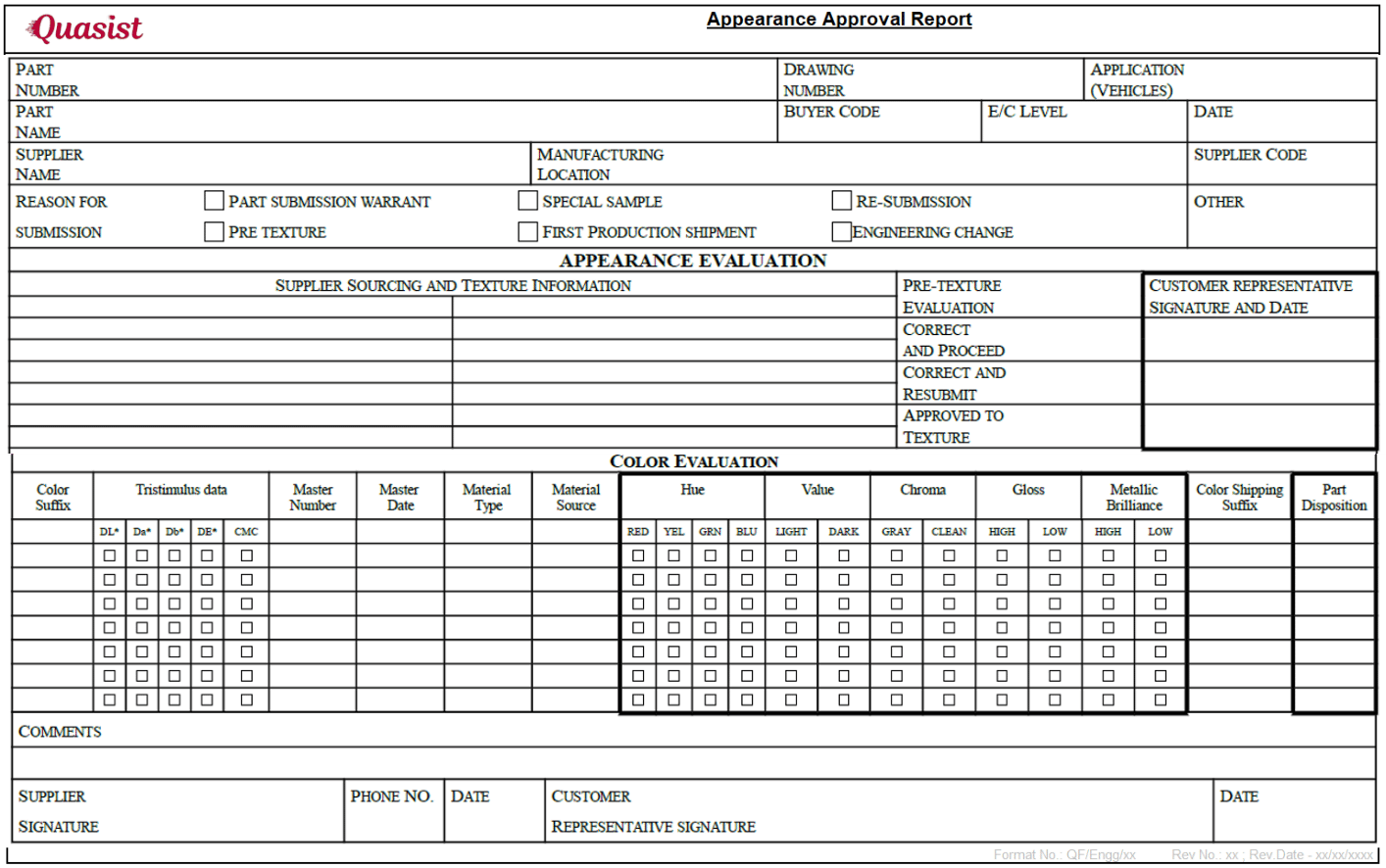

Key Elements or content of Appearance Approval Report #

A complete AAR includes the below points which is must to fill and submit.

1. Customer and Supplier Information #

- Customer name and part number.

- Supplier name and contact details.

- Submission date.

2. Part Identification #

- Part description and unique identifier.

- Revision level and drawing number.

3. Evaluation Criteria #

- Details of visual requirements such as color, gloss, texture, or pattern.

- Reference to approved samples or master standards.

4. Inspection Methodology #

- Tools and equipment used for assessment (e.g., color spectrophotometers, gloss meters).

- Inspection environment conditions such as lighting and viewing angles.

5. Approval Status #

- Clear indication of acceptance or rejection.

- Notes on any discrepancies and corrective actions required.

6. Signatures #

- Approval from the customer’s representative and the supplier.

Conclusion #

The Appearance Approval Report (AAR) is mandatory document as per PPAP process standard. This document helps to ensures the visual dimensions of a part meet customer demands. This will maintain your product quality and customer satisfaction.

If you want to learn quality tools and techniques, explore more other articles on our website.

Here, you get the complete knowledge you deserve…!