Precision measurement equipment involve a wide range of tools in industry, and each employs mechanical principles.

Depending on your field of expertise, you’re probably measuring and calculating real-world objects. This will be in terms of length, volume, area, pressure, etc.

This is especially true for professionals dealing with quality assurance and quality control.

To get all the measurements you need precision in it. To achieve precision you’ll need to use precision measuring instruments.

Precision measurement equipment are tools used to measure physical quantities and obtain measurements of real-world objects.

If you’re looking for a reliable supplier of precision measuring instruments, you may visit Eley Metrology and other similar providers online for high-quality tools and devices.

Now, you’re probably wondering what these tools and devices are.

Fortunately, you’re on the right article. Here’s a list of precision measuring instruments and their uses.

1. Micrometers

Micrometers are probably the most accurate hand-held tool as of this writing. If you need to measure as small as 0.0001 inches or 0.00254 millimeters, you’ll probably need this instrument.

There are many types of micrometers for special applications, including:

Blade Micrometer

– for measuring the diameter of inside, narrow grooves

Caliper-Type Micrometer

– for measuring small internal diameter

Spline Micrometer

– for measuring splined shaft diameter

Tube Micrometer

– for measuring pipe thickness

Point Micrometer

– for measuring root diameter

Micrometers can be mechanical, digital, or electronic. Electronic micrometers are typically IP67 compliant, which can withstand harsh environments where oils, water, dust, and dirt are prevalent. You can be assured that the measurements are accurate.

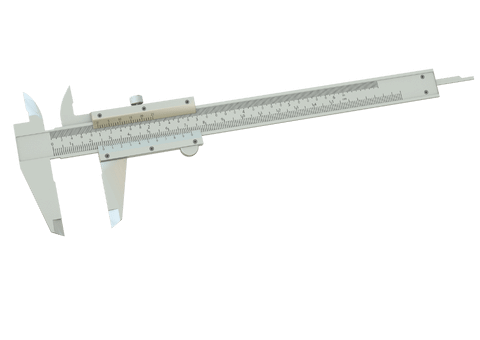

2. Calipers

Calipers are the best tool for the job if you need to measure an object as small as 0.001 inches or 0.0254 millimeters. They can measure the inside, outside, and depth of a particular object.

For example, you may use a caliper if you need to measure the internal diameter, external diameter, and depth of a small vial. You can use a ruler, but don’t expect an accurate measurement.

Calipers come in different types for special applications. These include:

- Depth Caliper – for measuring the depth of an object

- Offset Jaw Caliper – for measuring a stepped feature

- Point Jaw Caliper – for measuring uneven surfaces

- Blade Jaw Caliper – for measuring the diameter of narrow grooves

Calipers can be mechanical (Vernier caliper), digital, or electronic. In addition, they come in different lengths: six-inch, eight-inch, and 12-inch calipers. Wireless calipers are also available—ask your supplier for more information.

3. Height Gauges

Height gauges are one of the essential tools in quality control. These hand-held devices are designed to measure vertical distances. Also, they’re more reliable than calipers but not as expensive as other advanced tools.

Like micrometers and calipers, height gages come in different types for special applications, including:

- Vernier Height Gauge – This has more size variations and is more straightforward to operate than other types.

- Dial Height Gauge – This is easier to read than the Vernier scale and only available in a smaller size.

- Digital Height Gauge – This is more advanced and easier to read than most dial and Vernier scales.

- Electronic Height Gauge – This is the most sophisticated and advanced type. It has special features and functions that others—Vernier, dial, and digital—don’t have.

4. Depth Gauges

A depth gauge is a tool used by engineers—mechanical and manufacturing—and machinists to measure the depth of a recess, hole, groove, bored cavity, or other openings below the surface level of a particular object.

Depth gauges come in different types, including:

- Analog Depth Gauge – This features a dial and needle indicator to measure the depth of an object.

- Digital Depth Gauge – This works similarly to analog depth gauges but digital. It requires a power source—a battery—to function since there’s an electronic display.

- Depth Gauge Micrometer – This has a thimble and sleeve similar to a standard micrometer and is used in a similar manner.

- Rule Depth Gauge – This is a simpler version of the depth gauge, featuring a linear scale affixed to a bolt that can be adjusted to measure the depth of an object.

The primary use of depth gauges is to obtain precise and accurate measurements in machining and engineering applications.

5. Hardness Testers

Hardness testers are tools that determine the hardness of an object as well as other properties, such as ductility, strength, and wear resistance, empirically. Therefore, the skill and expertise of the operator are necessary; otherwise, the test may yield a higher percentage error.

Here are the common types of hardness testers:

- Rockwell Hardness Tester – This is the most common hardness tester available. It is used to determine the hardness of metals and hard plastics.

- Brinell Hardness Tester – This is the oldest type of hardness tester often used to determine the hardness of a coarse-surfaced object (e.g., forgings and castings).

- Vickers Hardness Tester – This is developed to be an alternative to Brinell testers. Unlike other types, it can determine the hardness of soft and thin metals, such as aluminum foil.

- Knoop Hardness Tester – This is an alternative to the Vickers tester. It can determine the hardness of brittle materials, such as thin ceramics.

- Shore Hardness Tester – Also known as shore durometers, shore hardness testers are developed to determine the hardness of rubbers and plastics.

6. Surface Roughness Testers

Surface roughness testers are tools use to determine the roughness or smoothness of a surface—hence the name. Aside from that, they can also be used to determine the material’s durability. For example, rougher objects are more susceptible to wear and tear than smoother ones.

Surface roughness testers fall into two categories: contact and non-contact. Contact surface testers work by running the stylus part of the tool across the surface to get a reading. On the other hand, non-contact surface testers use light instead of a stylus to get a reading.

Final Thoughts

Precision measurement equipment are use to obtain accurate measurements of real-life objects. They’re often used during quality control operations to ensure quality throughout the process. Since these instruments aren’t economical, it’s important to choose the type of instrument suitable for the task you want to accomplish. Doing so will also help achieve better and more accurate results.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.