Defect vs Defective is important topics for the quality engineers.

We use problem solving tools and techniques for continuous improvement in an organisation. And the data of defect and defectives are needed for the analysis.

Therefore it is essential to know the concept of defect and defectives.

What is mean by defect? #

A defect occurs during any process when the outcome of the process is not the expected outcome.

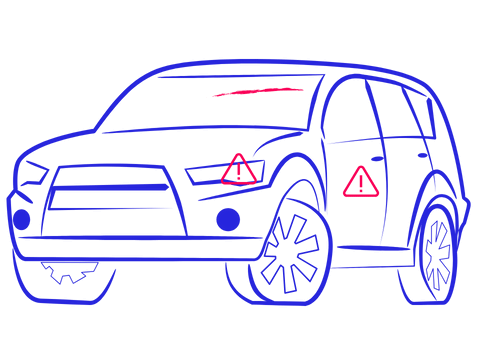

For example, if you manufacture a car then scratches on the car are one defect. Also dent on car is one defect.

The defects are

- scratches on front glass

- Faulty head light

- Dent on door

- Fuel tank open

What is defective? #

The defective is the product which has one or more defects.

Additionally, an item is only defective when it is considered unacceptable due to one or more defects.

Due to one or more defect in the car, the car becomes defective.

You can seen in example there are 5 cars are defectives.

Difference between defect and defective #

| Defect | Defective |

|---|---|

| Not the expected outcome. | It is totally unacceptable for use. |

| Not expected outcome due to non-conformity in the product. | It is considered unacceptable due to one or more defects. |

| Example, – Scratch – Dent – Damage – Specification not ok. | Example, – Consider we have one part that has one or many defects, that product is considered defective. |

As we learn in past post about what is defects and impact of defect in process.

So in the series of how to measure the defects, we need three methods to measure defect level and impact of defect.

- The 1st method is Process Yield. We learn that in our post, What is Process Yield? it is very important concept for Quality Engineer.

- The 2nd method is PPM calculation. This also you can learn in the post, PPM | the way of measuring defects.

- Now the 3rd one is DPU and DPMO, The complete concept of DPU and DPMO you will learn.

So, for all the above method, it is very important to know about what is Defect? and What is Defective?. These terms is helpful in measurement of defect level in manufacturing processes.

Now, you may confuse about what is exactly the defect opportunity means.

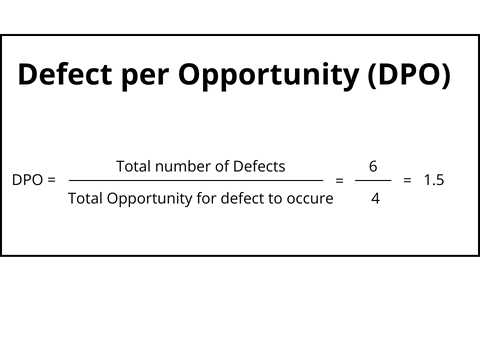

What is defect per opportunity? #

Lets take a look on the formula for the DPO,

Let’s take an example, so our concept of defect per opportunity will clear easily,

Assume that we are the car manufacturer, so our final outcome will be brand new car.

Now there are a opportunity to produce 4 defects in the car,

- Front glass scratch

- Dent on door

- Headlight fault

- Rear dent

Now from above example, We say that

- Car no. 2 having 2 defects.

- And car no. 7 having 4 defects.

- Also we have 2 defective vehicles (No. 2 & 7) having the respective 2 or 4 defects in each car.

now the defect per opportunity is,