let’s look at the important concept of process yield, to measure the level of defects and impact of defect in a process.

How are the level of defect measured?

We’ll use “p” to represent the number of defective units produced at a process step, divided by the total number of produced units going into the process step.

p = number of defective units / total number of produce unit

This is also known as the fraction defective. OR sometimes called the defect rate or the failure rate, because you hear those terms.

p = fraction defective

And if you convert that into a percentage, then we get the percentage defective.

How to calculate Process Yield?

So, on the other hand, the yield at a process step which represents the number of good units produced at that step, divided by the total number of units going to that step, is going to be equal to (1 – p).

Yield = good units produced at a process step / total unit going into the process step

Yield = 1 – p

So (1 – p) is the percentage of units that complete a sub process, or a part or a process step meeting quality guideline, without being scrapped, re-tested or reworked.

So, if you have more than one process step or more than one part to make your product, where n is a number of process steps or parts then, the overall good units coming out of the entire process is going to be the yield at each process step (1 – p) ^ n.

n = Number of processes (steps or part)

Process Yield = (1 – p) ^ n

Now, just a note here, we’re going to use the term process yield, but this is also referred to as, first pass yield or first-time yield or throughput yield and these are sometimes used interchangeably.

Although typically rule throughput yield is normally given as the probability of manufacturing a part or performing a service process, that you can perform all the required steps without any failures.

Whereas, first-pass yield or does not normally consider that but, it it depends on the reference.

We’re going to call it process yield means, the yield at each step (1 – p) ^ n or n is the number of steps.

And just one variation on that, is if you have different yields at the each step, so yield at step one, we call ‘a’, yield at step two is called ‘b’, yield step three is called ‘c’ .

You multiply all these three together to get the process yield.

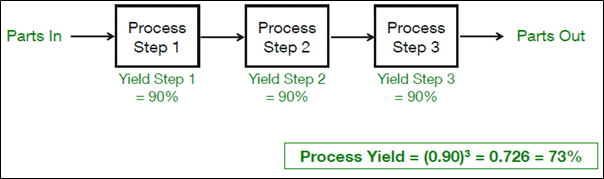

So let’s do some examples, here we, have a three step process and the process yield defined as a good parts out, divided by the total part in.

Examples of process yield

Example 1:

So for example, if we start with ten parts into process up one, and get ten good parts out, then the yield is going to be 10 /10 or 100 % , for that per system.

For process step two, we get to have 10 parts going in and only nine out. So the process yield for step two is going to be 9 /10 or 90%.

For step three, those nine parts go in and nine parts come out. So here, we have yield of 9 /9 also 100%.

The total yield as we learned, we have to multiply all the yields together. So we have (100 * 90 * 100) and we end up then, with an overall yield of 90%. And we can also say, I’ve written over here – good parts out is 9, parts in is 10, 9 /10 is 90%, okay.

Example 2:

So, let’s look at the three processes step then with each 10% fraction defective and calculate our final process yield.

We said that the fraction defective is equal to P.

Here p is equal to 10% or 0.1 We have three process steps. n = 3 here, and this means then, we have fraction good parts coming out of each step is (1 – p ) = (1 – 0.1) = 90% (0.9). And we can then calculate (0.9) ^ 3 to give us an overall process yield of 73%.

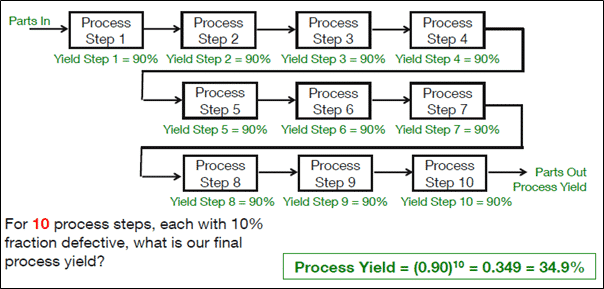

Example 3:

How do we calculate this?

Before (0.9) ^10, we end up with only 34.9 good parts coming out of our process.

Big perspective of process Yield

For a 1000 operation steps, each step with 0.99 (99%) yield. Our overall yield is 0.00432% and what if we have 10000 operation steps. Each with 99% defective, 1% fraction defective, 99% yield, pretty much zero.

By the time you take (0.99) ^10000 you don’t have any good parts out.

Now,

Why is Process Yield relevant? What could this be?

Well, since we work in car manufacturing company, assume a car consists of 10,000 parts or processes.

let’s look at this, for 10,000 process steps. Each with 1% fraction defective, each with 99% yields, we just said, you don’t get any cars out.

Source by TUM: Technische Universität München