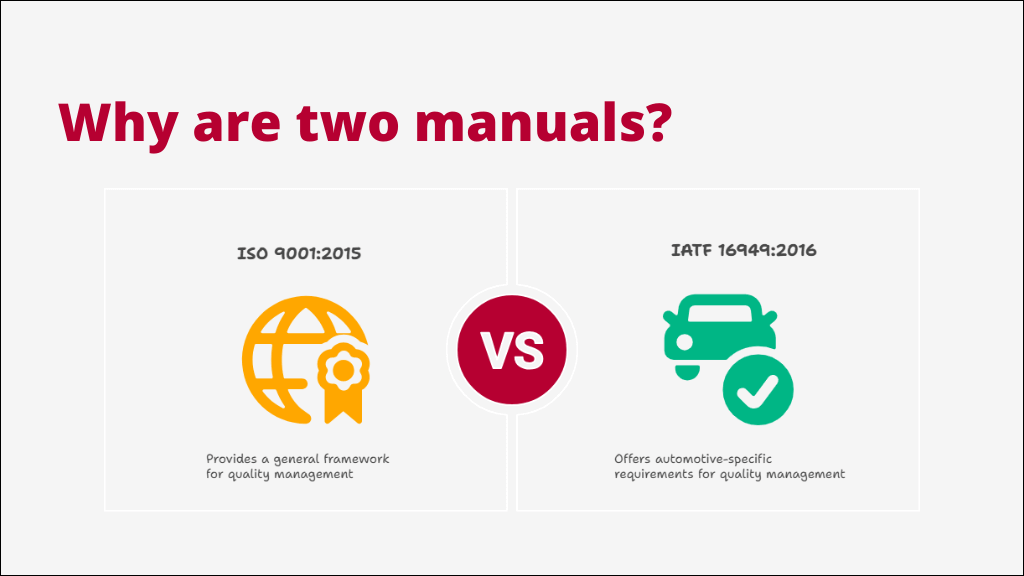

In the automotive manufacturing industry, quality management is most important. To make sure consistent product quality throughout global supply chain, the automotive industry depends on internationally recognized standards. Two of the most important quality standards are ISO 9001:2015 and IATF 16949:2016. However, many professionals has a doubt: Why there are two separate manuals? It would be more efficient to have one common/combined document?

This article helps you to clarify why these two separate standards exist, their relationship, and how organizations should follow them.

Understanding the Two Standards

1. ISO 9001:2015 – The Foundation of Quality Management System

ISO 9001:2015 is an internationally recognized standard developed by the International Organization for Standardization (ISO) body. It has the core requirements for a quality management system (QMS), which is applicable to all organization, regardless of it’s size (small, medium or large scale), type of industry, or location.

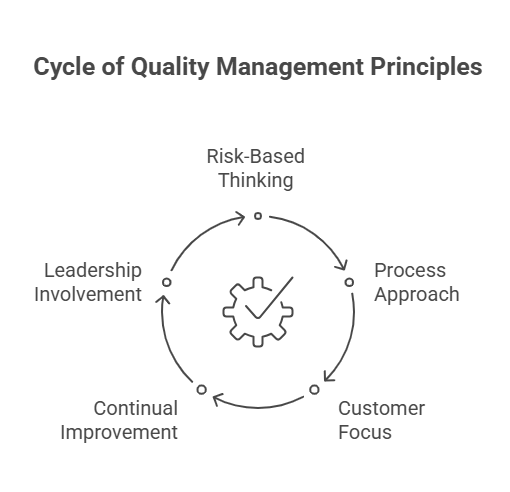

Key features include in ISO 9001:2015 are:

- Risk-based thinking

- Process approach

- Customer focus

- Continual improvement

- Leadership involvement

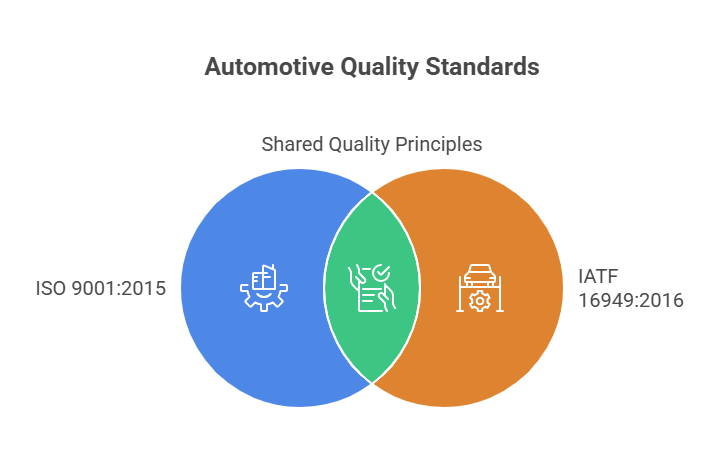

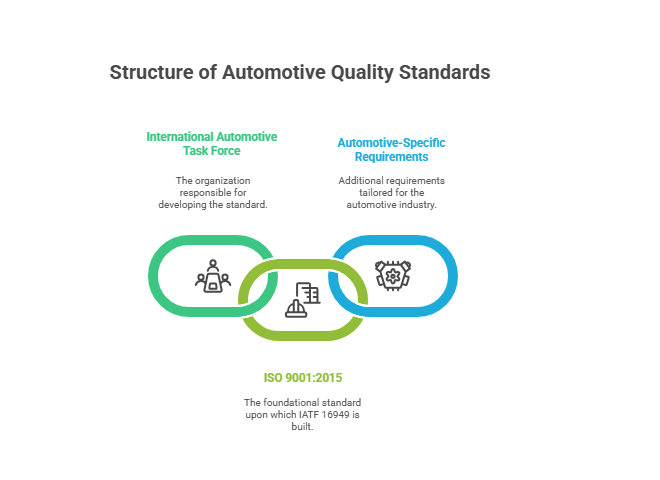

ISO 9001 works as the baseline for quality management and is the core structure on which many sector-specific standards are built. Other standards take a reference of this as a baseline.

2. IATF 16949:2016 – Automotive-Specific Quality Management System Requirements

IATF 16949:2016 was developed by the International Automotive Task Force (IATF) in conjunction with ISO. It supplements the ISO 9001:2015 standard by adding automotive-specific requirements to consider the needs of the automotive supply chain.

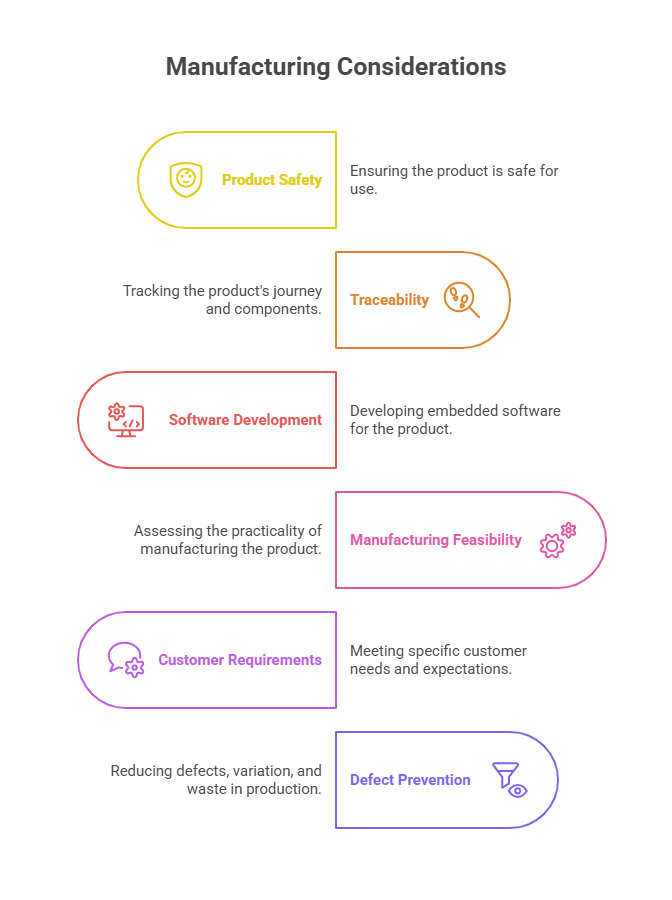

It includes additional requirements than ISO, such as:

- Product safety

- Traceability

- Embedded software development

- Manufacturing feasibility

- Customer-specific requirements

- Defect prevention and reduction of variation and waste

IATF 16949 is not a stand alone standard. It must be used along with ISO 9001:2015 standard. You have to follow or keep both standard to implement the IATF 16949 Automotive QMS system.

Why Two Manuals Instead of One?

This is a common question/concern raised by quality professionals and auditors among the industry.

There is a reason here’s, why two separate manuals exist:

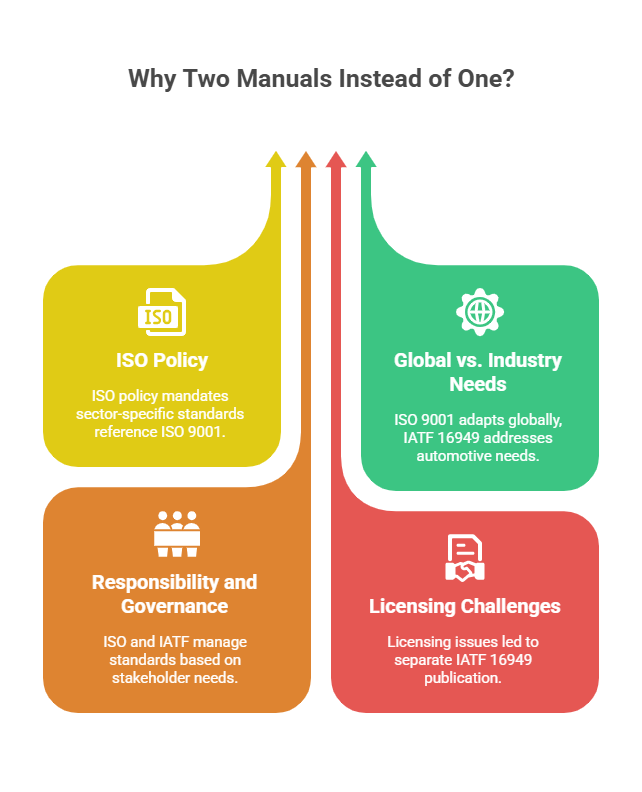

1. ISO’s Policy on Sector-Specific Standards

ISO has a policy that sector-specific standards cannot duplicate or rewrite ISO 9001 requirements. Instead, they must reference ISO 9001 and only add or supplement requirements as necessary.

This ensures:

- Clarity of ownership between ISO and sector groups

- Integrity of the ISO 9001 framework

- Avoidance of conflicting interpretations

Hence, IATF 16949:2016 is published separately to comply with ISO’s guidelines.

2. Global Applicability vs. Industry-Specific Needs

- ISO 9001 is a generic quality standard applicable to any industry.

- IATF 16949 focuses solely on the automotive sector, with its own unique risks, regulatory demands, and customer expectations.

By keeping the two manuals separate, each can evolve independently. ISO 9001 can adapt to global business needs, while IATF 16949 can keep pace with automotive-specific challenges like functional safety, embedded software, and product recalls.

3. Responsibility and Governance

- ISO 9001 is managed by the ISO/TC 176 committee.

- IATF 16949 is governed by the IATF consortium (members include OEMs like Ford, GM, BMW, etc.).

Maintaining separate documents allows each organization to manage and update the standard based on the specific stakeholder needs.

4. Official Reason: Licensing & Publication Challenges

One of the most important and practical reasons:

The IATF and ISO were not able to reach a licensing agreement to publish IATF 16949 in an integrated document. In order to not further delay the launch of the new IATF 16949 standard, the IATF decided to publish in a two-manual format.

Before releasing IATF 16949:2016, the IATF confirmed with international accreditation organizations that other industry sectors also use a two-manual format to define sector-specific requirements. Although this format is not optimal, it was found to be effective for implementation and auditing.

Additionally, the IATF maintains strong cooperation with ISO through its liaison committee status, ensuring continued alignment with ISO 9001 even though the standards are published separately.

Challenges of Two Manuals

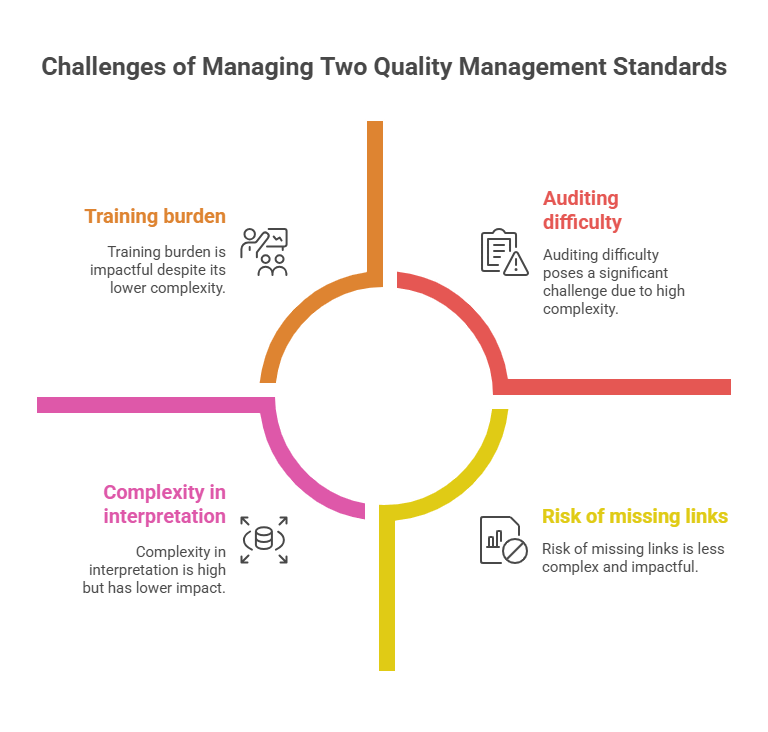

We know there is a logical thinking behind these two standards. But still having two manuals comes with some real-world challenges:

- Complexity in interpretation – Users must constantly look into or refer between ISO 9001 and IATF 16949. IATF standard just mention the ISO clause in standard, therefore user must have both standard open to understand and apply the clause.

- Training burden – Employees need to be trained on both documents. Or the trainer should follow both standard in IATF training.

- Auditing difficulty – Auditors must make sure the compliance with both the base (ISO) and supplementary (IATF) requirements.

- Risk of missing links – There are a chances of overlooked to most important cross-references, leading to non-conformities.

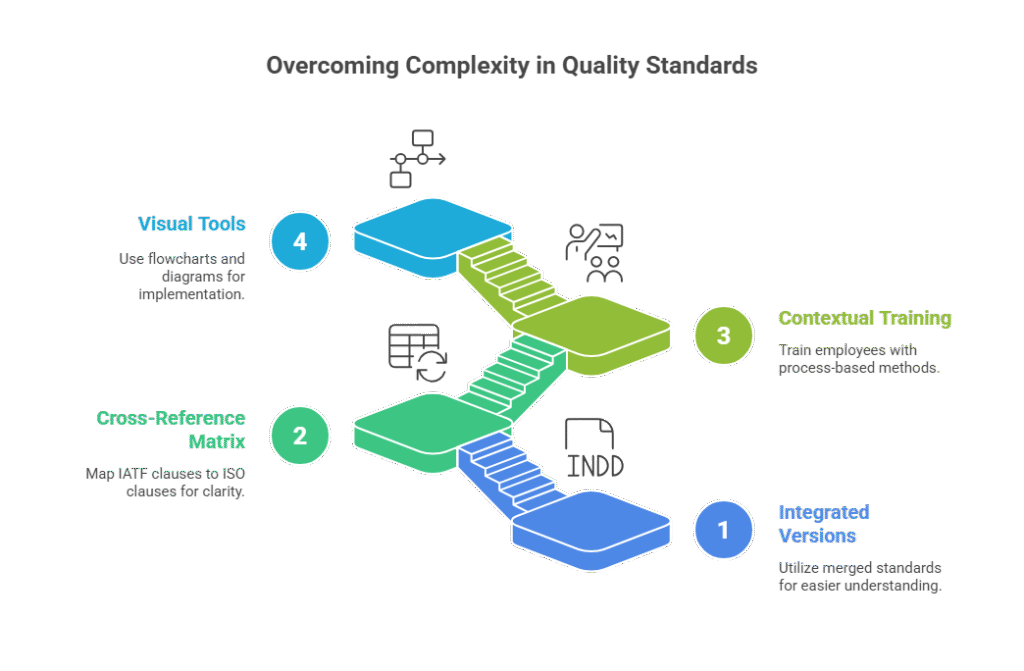

How to Manage the Two-Manual Challenge

Here are some practical ways to overcome the complexity:

1. Use Integrated Versions

Many certification bodies and consultants tried to solve this issues by creating integrated version of both standards. They offer integrated versions of ISO 9001 and IATF 16949 with both requirements shown side-by-side or merged together for easier understanding and implementation.

2. Implement a Cross-Reference Matrix

Create a cross-reference matrix that involve mapping of each IATF clause to its corresponding ISO clause. This helps teams to understand the relationship and scope of each requirement.

3. Train with Context

Don’t focus on to train employees separately on ISO and IATF requirements. Implement the system in process and use process-based training that contextualizes both standards into your company’s operations/processes.

4. Use Visual Tools

Process flowcharts, turtle diagrams, and SIPOCs can help to translate standard requirements into visual workflows, make them easier to understand and implement.

Conclusion

While having two manuals – ISO 9001:2015 and IATF 16949:2016 – can be burden at first, but the separation exists for good reason. ISO 9001 having the universal framework for quality, and IATF 16949 build based upon it with added automotive-specific requirements.

Understanding this difference or structure helps organizations:

- Avoid confusion during implementation

- Align better with certification requirements

- Do continual improvement specific to automotive sector

By help of right tools, training, and mindset, quality professionals can use both standards effectively.

Do you work in automotive quality management? How do you manage the two-standard challenge? Share your strategies in the comments or connect with us for implementation support.