Spot welding is proven and one of the oldest welding process. It is use in a wide range of industries, specially for sheet metal assembly for vehicle bodies and its components.

This is a type of resistance welding, where spot weld are made at regular intervals on overlapping sheets of metal. The primary purpose of spot welding to join two parts or sheets normally up-to 3mm in thickness. Thickness of the parts to be weld should be equal or the ratio of thickness should be less than 3:1. The strength of the joint depends on the number and size of the welds. Spot-weld diameters range from 3 mm to 12.5 mm.

In the types of welding all processes covered in two basic categories.

1. Pressure welding or Plastic welding or Solid state welding – Metal parts are heated in plastic state and join together with the help of external pressure. E.g. Spot / Resistance welding

2. Non-pressure or Fusion welding – Metal parts kept join and heated at joined stage. Then the metal got melted and fused together at molten temperature then got solidify. E.g. Arc welding.

How spot welding works #

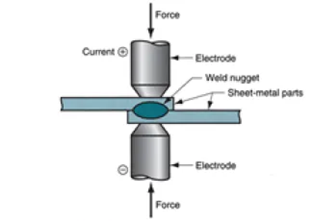

Spot welding is one form of resistance welding, which is a method of welding two or more metal sheets together without using any filler material by applying pressure and heat to the area to be weld.

The process is use for joining sheet materials and uses shaped copper alloy electrodes to apply pressure and convey the electrical current through the work-pieces. In all forms of resistance welding, the parts are being heated. The material between the electrodes yields and is squeeze together. It then melts, destroying the interface between the parts. The current is switched off and the “nugget” of molten materials solidifies forming the joint.

To create heat, copper electrodes pass an electric current through the work-pieces. The generated heat depended on the electrical resistance and thermal conductivity of the metal, and the time that the current is applied. The heat generate is expresses by the equation:

E=I2*R*t

where E is the heat energy, I is the current, R is the electrical resistance and t is the time that the current is apply.

Copper is use for electrodes because it has a low resistance and high thermal conductivity compared to most metals. This ensures that the heat is generate in the work-pieces instead of the electrodes.

Materials suitable for spot welding #

Steel has a higher electrical resistivity and lower thermal conductivity than the copper electrodes, making welding relatively easy. Low carbon steel is most suitable for spot welding. Higher carbon content or alloy steel tend to form hard welds that are brittle and could crack. Aluminium has an electrical resistivity and thermal conductivity that is closer to that of copper. However, aluminium’s melting point is much lower than that of copper, making welding possible. Higher levels of current must be use for welding aluminium because of its low resistivity.

Galvanized steel (i.e. steel coated with zinc to prevent corrosion) requires a different welding approach than non-coated steel. The zinc coating must first be melt off before the steel is join. Zinc has a low melting point, so a pulse of current before welding will accomplish this. During the weld, the zinc can combine with the steel and lower its resistivity. Therefore, higher levels of current are require to weld galvanize steel.

How to set the welding parameter for spot welding? => Spot Welding Parameters

What are the Spot welding / Resistance welding Parameters? #

Spot welding parameters include:

- Electrode force

- Diameter of the electrode contact surface

- Squeeze time

- Weld time

- Hold time

- Weld current

Electrode force #

In spot welding oth electrodes come together and squeeze metal sheets, both sheets with join together using the heat created.

For joining metals together we need large electrode force, otherwise welding will not happen or at low quality. If electrode force is large then also it will be the problem. Higher electrode force will leads to high current, this will produce more spatters and elctrodes may stuck into sheet.

The good target value for electrode force is 90N per mm2.

Diameter of the electrode contact surface #

One of the key requiremet from spot welding are to have a nugget diameter as per specification. The nugget Diametwe should as per below formula.

Calculate Spot Welding nugget diameter #

Nugget Diameter = 5*√t

Where t= Minimum thickness between two sheet being welded.

Resistance spot welding is done correctly when we meet the result of nugget diameter. Weld must have a nugget diameter of 5*√t. Where “t” is thickness of sheets being weld.

For explanation, in spot welding we weld two sheets. Both are 1 mm in thickness, then according to formula 5*√t, nugget should be minimum 5 mm. So, the electrode diameter is selected based on the required nugget diameter. It is slightly greater than nugget diameter.

For example, welding of both 1 mm sheet thickness need an electrode with contact diameter 6 mm. Generally trhe use of 6mm electrode diameter is good for the thickness of 0.5 to 1.25 mm as per ISO standards considering new electrode.

Squeeze time #

Squeeze time is cosider as time interval between start of electrode force to first application of current. The squeeze time helps to maintain the desired position of electode and sheet before starting the current. Basically it is help to delay the current.

Weld time #

Time to applied welding current between electrode and sheet metals are considered as weld time. The weld time is measured and set in cycles of voltage. In spot welding parameter all timing functions are measure in cycles.

One cycle is 1/50 of a second, that means in a 50 Hz power system. (When the weld time reference took from American literature, the number of cycles needs to be reduced. This is due to the higher frequency of 60Hz used in the USA.)

What is correct value of weld time required to get good weld spot?

Well it is difficult to get exact value of specific weld time.

Weld time points to consider before setting Spot Welding Parameters #

But you can consider below points for instance,

- Weld time should be as short as possible.

- The weld current should give the best weld quality as possible.

- The weld time shall cause the nugget diameter to be big when welding thick sheets.

- The weld time might have to be adjusted to fit the welding equipment in case it does not fulfill the requirements for the weld current and the electrode force. (This means that a longer weld time may be needed.)

- The weld time shall cause the indentation due to the electrode to be as small as possible. (This is achieved by using a short weld time.)

- The weld time shall be adjusted to welding with automatic tip-dressing, where the size of the electrode contact surface can be kept at a constant value. (This means a shorter welding time.)

If you are welding sheet more than 2 mm then the best practice is to divide the weld time into more impulse as per requirement. This method will avoid more heat energy, and provide good aesthetic spot weld. Strength can be the factor you need to consider here.

By multiplying the thickness of the sheet by 10, a best value for weld time can be calculated. When welding two sheet metals with both have thickness of 1 mm, an proper weld time is 10 cycles (50Hz). But it is advisable to have a experiement to set the correct weld time with relationto other parameters.

Hold time (cooling-time) #

Hold time is after welding time, when electrodes still closed together to cool down the weld. Understand from a welding technical point of view, the hold time is most interesting & essential welding parameter.

Hold time is helps to allow weld area to solidify at instance before release of welding parts. But it should not be more as it leads to heat ransfer to the electrodes. If heat is pass to electrodes then electodes will wear rapidly.

Also if the weld time is more then due to carbon content in the material, weld become more brittle and leads to weld failure. But in case of galvanised steel long time is always recommended.

Weld current | Important Spot Welding Parameters #

Weld current is actual current flow though the welding circuit during making of weld. Therefore weld current is baseline parameter of spot welding.

Two things are consider to controlled the amount of weld current.

- First, transformer switch setting determines amount of weld current available to do weld. Adjust top switch correctly so that appropriate welding current achieved.

- Second, available percent of current to make a weld by setting the current percent control. Low percent current setting are not recommended.

The weld current must keep as low as possible. Also consider the weld spatter factor while setting weld current. Adjust weld current gradually to check occurrence of weld spatter at level. This method tells us the presence of weld current and its level.