In the manufacturing industry, the important knowledge for quality engineers is core tools. The SPC calculator here to calculate the process capability.

This SPC calculator helps you to understand your process behavior.

As a manufacturing expert, you should know your process variation. The SCP calculator is an important tool to get the exact result of your process.

Is your process capable or not capable?

It is a simple tool, you need to measure the data and put the data into the below fields and you will get the results.

SPC Calculator Tool

Terms used in SPC calculator

SPC tool Header information

Part Name & Part Number: Mentioned which product is impacted by the process you are analyzing.

Instrument: It is the name of the measuring instrument you will be using to measure data.

Specification: Write the specification of the dimension you will be measuring for the SPC analysis.

Sample size: The total number of samples measured at a time. Here we can say we have a sample size of 5 parts at one time. Which is also called a subgroup of a sample.

Operator Name: Name of the operator who running the process. Or measuring the data or being responsible for the process improvement.

Least count: Least count of the measuring instrument. In simple words, the least measurement can done by the instrument.

Process Name: Name of the process for which the SPC analysis is done. e.g. Welding process, Bending process, stamping process, etc.

No of Decimal: It depends on how your instrument can record or measure the data. It can be measured up to 2 decimals, 3 decimals, etc.

UTL (Upper Tolerance Limit) & LTL (Lower Tolerance Limit).

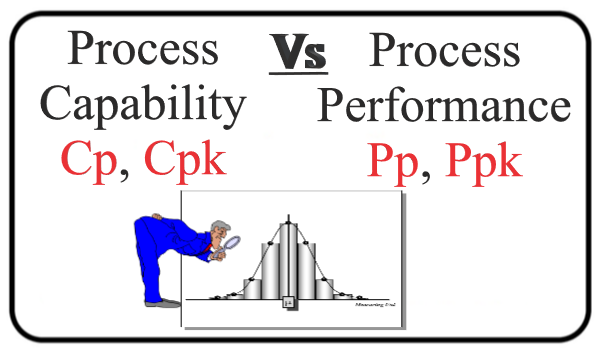

Cp & Cpk: It is the process capability indices. Which shows us whether our process is capable or not.

Final Result: If the Cpk is greater than 1.33 then we can say our process is capable. Sometimes the Cpk value is provided by the customer. Some OEM’s target for Cpk is 1.67.

And Cp will always be greater than Cpk, it is the thumb rule.

How to Use this SPC Calculator tool

- The first step is to fill in the SPC tool header information. This will give you an idea for which product and process the SPC study will done.

- Measure and record the data in the sheet. As per this tool, the total quantity is 50 Parts. The Parts need to be measure subgroup-wise.

- Enter the data into the table.

- Enter the UTL and LTL in the tool.

- Based on the data you will get the final result of whether a process is capable or not. Also, the Cp & CPk values will be calculate based on that.

Why Should Use this SPC Calculator tool

As you know, before making any improvement in the process, you should know the process behavior.

The SPC tool and calculator are one of the tools to predict and understand the process behavior using the data.

Therefore it is one of the key documents in the PPAP as process capability analysis.

There are control charts represent based on data. We have here the Xbar and R chart.