Introduction

For instance, to know about the special processes in industry, will be the great for our career. As we see the surface treatment is the common process on all bare metal components before going to end user. either it will be done by OEM’s or by tier II suppliers. So we must have the knowledge of these processes.

Here we take a short look on powder coating process, so the highlights of this post is

What are surface treatment processes?

- Plating

- CED Coating

- Powder Coating

- Buffing/Mirror finishing

- Shot blasting

- Painting

- Surface Hardening

Why surface treatment?

So surface treatment is basically divided into two purpose/ major categories one is to cover the surface and other is to alter the surface. Therefore the answer for why surface treatment is

1- To improve aesthetics

2- To improve corrosion resistance

3- To control friction & wear

4- To change physical properties

5- To improve the hardness

Corrosion is a reaction between a metal and it’s environment, and both are

important in the process

What is powder coating?

As it is one of the surface treatment process therefore Powder coating is an advanced method of applying a decorative & protective finish to a wide range of materials & products that are used by both industries & consumers.

The powder used for the process is a mixture of finely ground particles of pigment & resin, which is sprayed on to a surface to be coated and similarly The charged powder particles adhere to the electrically grounded surface until heated & fused in to a smooth coating in a curing oven. So the result is a uniform, durable, high quality & attractive finish with the product.

As it is a fine process so the expectation on the product about coating is as

– Higher Quality

– Extremely Durable

– Environmentally Friendly

– Cost Efficient

Powder used for coating

Basically the powder is mixture of finely ground particles of pigment & resin. Therefore the mixture ingredients are melt mixed, cooled, and ground into a uniform powder, so in this mixture several particles are link together and form a powder coating film.

Pigment – Gives color and filling properties, light fastness, Heat stability, Water resistance.

EXENDERS – To reduce the cost, reduce Gloss, Improve film build and abrasion, workability. fillers

RESINS – Binds and wets the pigment, Resin giving fluidity to Powder film & it gives Adhesion, Gloss, Hardness & Durability.

ADDITIVE – Dispersing agent, flow, film leveling & provide special properties like antifungal & Mar proofness, Matting agent etc.

Application of powder coating

Powder coating applies in n number of industries and product ranges such as

- Domestic appliances

- House hold appliances

- Industrial application

- Automotive application

- Marine environments

Applications on different substrates

- All ferrous sheet metal & casting substrates

- Different grades of steel & cast iron derivatives

- Non ferrous sheet metal as well as casting substrates

- Aluminum, copper, brass,…etc & casting derivatives

- Fabric: different types of cotton clothe

Equipment and facilities for powder coating

The process is a set of subsequent processes and a many equipment and facilities used for powder coating process such as

- Filters (Disc/Cartridge) – It is used for collection of dust, impurities to better or continues flow of powder on the parts

- Oil Skimmer – It is designed to remove oil floating on a liquid surface

- Agitator unit – An agitator is device or mechanism to put something into motion by shaking or stirring

- Immersion heaters with temperature indicator controller – Immersion heaters are best suited for heating fluids in pressurized systems and tanks.

- Jigs, fixtures

- Tanks

- Rectifiers – Rectifier diodes are a vital component in power supplies where they are used to convert AC voltage to DC voltage.

- Oven

- Dryer – Dryer are used to remove excess moisture or other volatiles from coatings and various substrates Reduction and control of moisture levels in solid materials through heated drying

- Scrubber – Scrubbers are one of the primary devices that control gaseous emissions, It is an air pollution control systems designed to clean industrial exhaust streams of solid, liquid and gas particles before they are released into the atmosphere air.

- Safety requirements – Safety equipment must be ware by operator, without caring cause’s lungs & Respiratory problems with Operator

Instruments

- Conductivity meter

- Ph meter

- Laboratory – Powder coating lab should be available with all facility of testing

- Auto weighing machine

- Pressure gauge

- Powder coating spray booth with recovery system – Spray booth should be always covered with an appropriate space & Jigs for part & Operator movement while spraying

- Electrostatic spray Gun, power pack

- Timers with alarm system

- DM water plant with required capacity – Water selection – PH & TDS level. DM water should be used it’s free from all Mineral salts causing corrosion. Conductivity of DM water should be maintained below 50Ms

- Testing facilities for chemical analysis

- SST chamber as per ASTM B117 min 400 ltr

Chemicals use for bath preparation

- Degreasing chemicals

- Acid cleaning

- Activation

- Zinc phosphating

- Passivation

- Powder

Process sequence for powder coating

Degreasing process

Floating oil to be removed from the bath with oil skimmer.

Bath discard frequency.

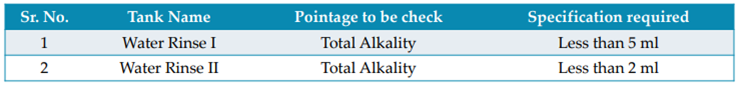

Water Rinsing

- Water – PH & TDS level if not within limit than DM water.

- To control drag out solution from process bath into rinse water.

- Remove of oil trace.

- Stop the chemical reaction.

- Prevent cross contamination of sub sequent process tanks.

- Minimize water consumption.

Acid Pickling

1- To removed oxide scale from hot worked or hot rolled steel.

2- To eliminates impurities such as inorganic contaminants, stains

3- To remove rust.

4- To remove welding scale & heat treatment scale.

5- To provides a light or micro-etched activation which promotes better adhesion.

Activation

Activation of the substrates is final step prior to the actual plating operation.

Purpose –

• To remove the final trace of oxides.

• To provide microscopic etch on the substrate which promotes

better adhesion.

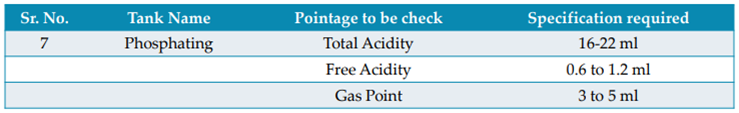

Zinc phosphate coating

• To protect parts from corrosion during powder coating.

• To provide strong bonding for better adhesion between sheet

metal & paint.

• Good solution life.

• Approx. coating weight is between 150-600mg/sq.ft

Passivation

• To convert zinc metal to a complex chromium compound to

give excellent corrosion resistance.

• To avoid white rust chromate conversion coating is helpful.

Dry off / drying in oven

– To dry of water content from surface in Oven

– To get good adhesion.

– Also applying compressed air supply

Types of oven –

– Batch production :- Box oven used

– Over head conveyor system :- Camel back oven used

– Ground conveyor :- Tunnel oven used

Oven Baking :-

• Oven baking temp range to be define between max. 5 unit difference e.g. 180 – 185 °C.

• Time tolerance for baking is 20-25 Min.

• Oven need to calibrate by thermometer. (Min once in a month)

• Also temperature indicator controller should be calibrate periodically.

• Poka-yoke must for higher & lower temp. control with hooter

Powder coating (Electrostatic Spraying)

- Uses air for atomization of powder.

- High voltage charge induced into spray pattern to add electrostatic charge for atomized particles.

- Part is having opposite charge.

- Powder deposition.

Purpose of Cleaning

To remove the oil, grease, dust, miscellaneous surface contaminates, pigmented drawing components, chips & cutting fluids.

Defect generated in powder coating

- Paint peel off

- Pin hole

- Blisters

- Uncovered

- Bubbles

- Touch up

- Scratches

- Craters

- Dust