Spot welding is proven and one of the oldest welding process. It is use in a wide range of industries, specially for sheet metal assembly for vehicle bodies and its components.

This is a type of resistance welding, where spot weld are made at regular intervals on overlapping sheets of metal. The primary purpose of spot welding to join two parts or sheets normally up-to 3mm in thickness. Thickness of the parts to be weld should be equal or the ratio of thickness should be less than 3:1. The strength of the joint depends on the number and size of the welds. Spot-weld diameters range from 3 mm to 12.5 mm.

In the types of welding all processes covered in two basic categories.

1. Pressure welding or Plastic welding or Solid state welding – Metal parts are heated in plastic state and join together with the help of external pressure. E.g. Spot / Resistance welding

2. Non-pressure or Fusion welding – Metal parts kept join and heated at joined stage. Then the metal got melted and fused together at molten temperature then got solidify. E.g. Arc welding.

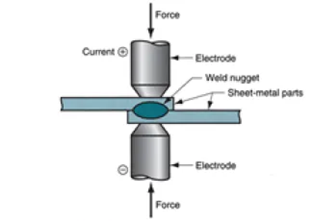

How spot welding works

Spot welding is one form of resistance welding, which is a method of welding two or more metal sheets together without using any filler material by applying pressure and heat to the area to be weld.

The process is use for joining sheet materials and uses shaped copper alloy electrodes to apply pressure and convey the electrical current through the work-pieces. In all forms of resistance welding, the parts are being heated. The material between the electrodes yields and is squeeze together. It then melts, destroying the interface between the parts. The current is switched off and the “nugget” of molten materials solidifies forming the joint.

To create heat, copper electrodes pass an electric current through the work-pieces. The generated heat depended on the electrical resistance and thermal conductivity of the metal, and the time that the current is applied. The heat generate is expresses by the equation:

E=I2*R*t

where E is the heat energy, I is the current, R is the electrical resistance and t is the time that the current is apply.

Copper is use for electrodes because it has a low resistance and high thermal conductivity compared to most metals. This ensures that the heat is generate in the work-pieces instead of the electrodes.

Materials suitable for spot welding

Steel has a higher electrical resistivity and lower thermal conductivity than the copper electrodes, making welding relatively easy. Low carbon steel is most suitable for spot welding. Higher carbon content or alloy steel tend to form hard welds that are brittle and could crack. Aluminium has an electrical resistivity and thermal conductivity that is closer to that of copper. However, aluminium’s melting point is much lower than that of copper, making Galvanized steel (i.e. steel coated with zinc to prevent corrosion) requires a different welding approach than non-coated steel. The zinc coating must first be melt off before the steel is join. Zinc has a low melting point, so a pulse of current before welding will accomplish this. During the weld, the zinc can combine with the steel and lower its resistivity. Therefore, higher levels of current are require to weld galvanize steel.

How to set the welding parameter for spot welding? => Spot Welding Parameters

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.