What is Defects & Discontinuity?

Defects : A flaw or flaws that by nature or accumulated effect render a part or product unable to meet minimum applicable acceptance standards or specifications. The term designates rejectability.

Discontinuity : An interruption of the typical structure of a material, such as a lack of homogeneity in its mechanical, metallurgical, or physical characteristics. A discontinuity is not necessarily a defect.

Weld Joint Discontinuity

- Misalignment (hi-lo)

- Underfill

- Concavity or Convexity

- Undercut

- Excessive reinforcement

- Improper reinforcement

- Overlap

- Burn-through

- Incomplete or Insufficient Penetration

- Incomplete Fusion Surface irregularity Overlap

- Spatter

- Cracks

- Porosity

DIMENSIONAL DEFECTS

A Dimensional defects are any defect that cause the weld metal. Parent metal, work piece to be out of specification or tolerance. Know more about the What is welding & types of welding processes.

Dimensional defects are mainly caused by improper set up or distortion. This should be managed before the welding process.

Misalignment

Definition

Amount a joint is out of alignment at the root

Cause

Carelessness. Also Also due to joining different thicknesses (transition thickness)

Prevention

Prevention: Workmanship. Transition angles not to exceed 2.5 to 1.

Repair

Grinding. Careful on surface finish and direction of grind marks. Inside of Pipe /Tube difficult.

UNDERCUT

Definition

A groove cut at the toe of the weld and left unfilled.

Cause

High amperage, electrode angle, long arc length, rust

Prevention

Set machine on scrap metal. Clean metal before welding.

Repair

Weld with smaller electrode, sometimes must be low hydrogen with preheat.

Undercut typically has an allowable limit. Different codes and standards vary greatly in the allowable amount.

INSUFFICIENT FILL / WELD SHIFT

Definition

The weld surface is below the adjacent surfaces of the base metal

Cause

Improper welding techniques

Prevention

Apply proper welding techniques for the weld type and position.

Repair

Simply weld to fill. May require preparation by grinding.

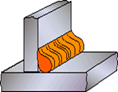

CONCAVE AND CONVEX WELD PROFILES

Definition

Concavity or convexity of a fillet weld which exceeds the specified allowable limits

CONCAVE WELD

The concave defect cause the weld to be weak across the throat of the weld (Middle).

Causes

- Travel speed is to quick

- Amps are to high

- Poor electrode Manipulation

CONVEX WELD

The convex defect cause the weld to become weak at the toes of the weld (outer edges).

Causes

- This is caused by :

- Travel speed being to slow

- Amps to low

- Poor electrode manipulation.

Prevention: Observe proper parameters and techniques.

Repair: Grind off or weld on. Must blend smoothly into the base metal.

BURN-THROUGH

Definition:

When an undesirable open hole has been completely melted through the base metal. The hole may or may not be left open.

Cause

Excessive heat input.

Prevention

Reduce heat input by increasing travel speed, use of a heat sink, or by reducing welding parameters.

Repair

Will be defined by standards. Filling may suffice. Otherwise, removal and rewelding may be required. Some standards may require special filler metal.

INCOMPLETE FUSION AND PENETRATION

Incomplete root fusion is when the weld fails to fuse one side of the joint in the root, and incomplete penetration occurs when both sides of the joint are unfused.

Some of the causes are:-

These defects can be reduced in welding by Using the correct welding parameters and Electrode size, This will give the correct arc energy Input.

Incomplete or Insufficient Penetration

Definition

When the weld metal does not extend to the required depth into the joint root

Cause

Low amperage, low preheat, tight root opening, fast travel speed, short arc length.

Prevention

Correct the contributing factor(s).

Repair

Back gouge and back weld or remove and reweld.

Incomplete Fusion

Definition

Where weld metal does not form a cohesive bond with the base metal.

Cause

Low amperage, steep electrode angles, fast travel speed, short arc gap, lack of preheat, electrode too small, unclean base metal.

Prevention

Eliminate the potential causes.

Repair

Remove and reweld, being careful to completely remove the defective area. This is sometimes extremely difficult to find.

SPATTER

Definition

Small particles of weld metal expelled from the welding operation which adhere to the base metal surface.

Cause

Long arc length, severe electrode angles, high amperages. Incorrect welding conditions and/or contaminated consumables or preparations, giving rise to explosions within the arc and weld pool

Prevention

Correct the cause. Base metal can be protected with coverings or hi-temp paints.

Repair

Remove by grinding or sanding. Sometimes must be tested as if it were a weld.

Crack

Solidification Cracking

Causes: –Large depth/width ratio of weld bead –High arc energy and/or preheat –Sulphur, phosphorus or niobium pick-up from parent metal

Hydrogen Cracking

Causes:

- Hardened HAZ coupled with the presence of hydrogen diffused from weld metal.

- Susceptibility increases with the increasing thickness of section especially in steels with high carbon equivalent composition.

- Can also occur in weld metal

- Increase welding heat beneficial

- Preheating sometimes necessary

- Control of moisture in consumables and cleanliness of weld prep desirable

Prevention

- Preheat slows down the cooling rate; this can help avoid martensite formation and supplies heat to diffuse hydrogen out of the material

- Low-hydrogen welding procedure

Lamellar Tearing

Causes: –Poor ductility in through-thickness direction in rolled plate due to non-metallic inclusions –Occurs mainly in joints having weld metal deposited on plate surfaces –Prior buttering of surface beneficial for susceptible plate

Surface Porosity

•Causes: –Excessive contamination from grease, dampness, or atmosphere entrainment –Occasionally caused by excessive sulphur in consumables or parent metal

Reinforcement

The amount of a groove weld which extends beyond the surface of the plate

- Excessive

- Insufficient

- Improper contour

Excessive Reinforcement

Definition

Specifically defined by the standard. Typically, Reinforcement should be flush to 1/16”(pipe) or flush to 1/8” (plate or structural shapes).

Cause

Travel speed too slow, amperage too low

Prevention

Set amperage and travel speed on scrap plate.

Repair

Remove excessive reinforcement and feather the weld toes to a smooth transition to the base plate.

Insufficient Reinforcement

Definition

Specifically defined by the standard. Typically, Underfill may be up to 5% of metal thickness not to exceed 1/32” as long as the thickness is made up in the opposite reinforcement.

Cause

Travel speed too fast.

Prevention

Use proper welding technique. Use backing or consumable inserts. Use back weld or backing.

Repair

Possibly simply increase the face reinforcement. If back welding is not possible, must remove and reweld.

Improper Weld Contour

Definition

When the weld exhibits less than a 1350 transition angle at the weld toe.

Cause

Poor welding technique

Prevention

Use proper techniques. A weave or whip motion can often eliminate the problem.

Repair

The weld face must be feathered into the base plate.

Overlap

Definition

When the face of the weld extends beyond the toe of the weld.

Cause

Improper welding technique. Typically, electrode angles and travel speed.

Prevention

Overlap is a contour problem. Proper welding technique will prevent this problem.

Repair

Overlap must be removed to blend smoothly into the base metal. Be careful of deep grind marks that run transverse to the load. Also be careful of fusion discontinuities hidden by grinding. Use NDT to be sure.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.