Curious to know entire series of quality management system document structure.

Every Engineer is struggling to learn QMS documentation or the documentation part of the job.

But why?

The reason is career growth and opportunity to work on quality system. Also the documentation is the part where management, customer and auditor are doing evaluation all the time.

Also you will be the documentation expert.

Why we do IATF documentation?

The QMS documentaion ensure that our company is compliance to quality assurance, regulatory and customer requirements.

It is a documented structure and framework of organizational processes align together to achieved objectives and goal of an organization.

By following these documentation structure companies are able to do

- Consistency and standardization

- Improvement in quality processes

- Comply with regulation and automotive requirements.

- Achieve customer satisfaction

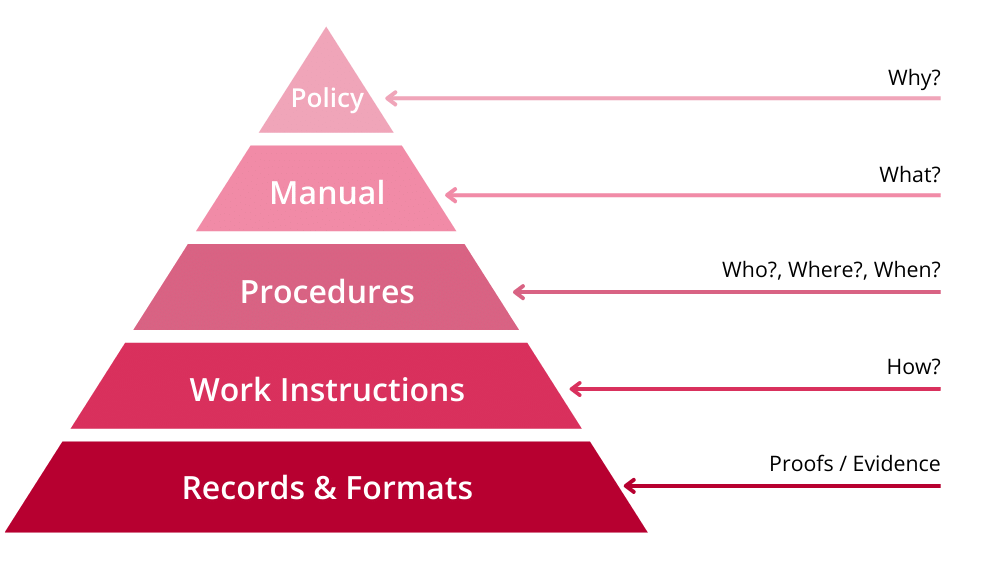

What are those documents? | level of documents in QMS

Quality Management System Document structure has 5 level of documents.

Quality Management System Procedures

Mandatory procedures

- Product safety procedure (4.4.1.2)

- Managing calibration /verification records procedure (7.1.5.2.1)

- Training, awareness and competency procedure (7.2.1)

- Procedure to verify competence of internal auditors (7.2.3)

- Employee motivation procedure (7.3.2)

- Procedure of maintaining customer engg. standards/specifications (7.5.3.2.2)

- Procedure for Design and Development (8.3.1.1)

- Procedure to identify special characteristics (8.3.3.3)

- Supplier selection process (8.4.1.2)

- Identify and control externally provided processes, products and services (8.4.2.1)

- Ensure compliance with statutory and regulatory requirements of purchased processes, products and services (8.4.2.2)

- Evaluation of supplier performance procedure (8.4.2.4)

- Process to control and react to changes in product realization (8.5.6.1)

- Process for management of the use of alternate control methods (8.5.6.1.1)

- Rework procedure (8.7.1.4)

- Repair procedure (8.7.1.5)

- Nonconforming product handling procedure (8.7.1.7)

- Internal audit procedure (9.2.2.1)

- Procedure of problem solving (10.2.3)

- Use of error-proofing methodologies procedure (10.2.4)

- Procedure of continual improvement (10.3.1)

Other Required Procedures

- Procedure for Document and Record Control (7.5)

- Procedure to determining the context of the organization and Interested Parties (4.1 & 4.2)

- Procedure for Addressing Risks and Opportunities (6.1)

- Production Part Approval Process Procedure (8.3.4.4)

- Workplace Organization (5S) Procedure (7.1.4)

- Laboratory management procedure (7.5.1.3)

- Procedure for second-party audits (8.4.2.4.1)

- Process for Equipment Maintenance (8.5.1.5)

- Tooling Management procedure (8.5.1.6)

- Verification and acceptance of conformity of externally provided products and services (8.6.4)

- Customer satisfaction monitoring procedure (9.1.2)

- Procedure for Management Review (9.3)

- Warranty management process (10.2.5)

Work Instructions

- Process work instruction

- Incoming inspection work instruction

- Machine work instruction

Documents & Records/Forms

This list covers the IATF requirement and respective documents or record or work instructions along with respective department. You can find the quality management system document structure in below table.

| IATF Clause | Type of Doc | Procedure / Document / Record / WI |

|---|---|---|

| 4.0 Context Of The Organization | ||

| 4.1 Understanding The Organization And Its Context | ||

| 4.2 Understanding The Needs And Expectations Of Interested Parties | Procedure | Determining Context of the Organization and Interested Parties |

| Record | Conformance Evaluation | |

| 4.3 Determining The Scope Of The QMS | Document | Scope of the Quality Management System |

| 4.3.2 Customer-specific requirements | Document | List of Interested Parties and Customer Specific Requirements |

| 4.4 QMS and Its Processes | ||

| 4.4.1.1 Conformance of products and processes | ||

| 4.4.1.2 Product safety | Mandatory Procedure | Product Safety Procedure |

| 5 Leadership | ||

| 5.1 Leadership And Commitment | ||

| 5.1.1.1 Corporate responsibility | Document | Corporate Responsibility Policy |

| 5.1.1.2 Process effectiveness and efficiency | ||

| 5.1.1.3 Process owners | ||

| 5.1.2 Customer Focus | ||

| 5.2 Policy | Document | Quality policy |

| 5.2.1 Establishing The Quality Policy | ||

| 5.2.2 Communicating The Quality Policy | ||

| 5.3 Organizational Roles, Responsibilities And Authorities | Document | Roles & responsibilities |

| 5.3.2 Responsibility and authority for product requirements and corrective actions | ||

| 6 Planning | ||

| 6.1 Actions To Address Risks And Opportunities | Procedure | Addressing Risks and Opportunities |

| Registry of Key Risks and Opportunities | ||

| 6.1.2.1 Risk analysis | Risk analysis | |

| Procedure | Procedure for FMEA Risk Assessment | |

| Record | Design & Process FMEA Form | |

| 6.1.2.2 Preventive action | Record | Preventive action |

| Record | Preventive Action Record | |

| 6.1.2.3 Contingency plans | Document | Contingency plan |

| 6.2 Quality Objectives And Planning To Achieve Them | Document/Record | Quality Objectives and planning |

| 6.3 Planning Of Changes | ||

| 7 Support | ||

| 7.1 Resources | ||

| 7.1.2 People | ||

| 7.1.3 Infrastructure | ||

| 7.1.3.1 Plant, facility, and equipment planning | Document/Record | Plant and Lines Layout |

| Document/Record | Validation Plan | |

| Document/Record | Manufacturing feasibility assessments (Capacity Planning) | |

| 7.1.4 Environment For The Operation Of Processes | Procedure | Workplace Organization (5S) |

| Document/Record | Workplace Organization (5S) Audit Form | |

| 7.1.5 Monitoring And Measuring Resources | Document/Record | Plan for Preventive Maintenance of Equipment |

| 7.1.5,1.1 Measurement systems analysis | Procedure | Control of Gauges |

| Document/Record | MSA Study | |

| Document/Record | Measurement System Analysis Plan | |

| Document/Record | Measurement System Analysis Form | |

| 7.1.5.2 Measurement Traceability | Procedure | Equipment Maintenance and Measuring Equipment |

| Document/Record | Calibration Certificate of Master Equipment | |

| Document/Record | Maintenance and Calibration Record | |

| 7.1.5.2.1 Calibration/verification records | Mandatory procedure | Calibration |

| Document/Record | Calibration / verification records of gauges and equipments | |

| Document/Record | List of Equipment | |

| 7.1.5.3 Laboratory requirements | Procedure | Laboratory management |

| Document/Record | Test Schedule Form | |

| 7.1.5.3.1 Internal laboratory | Document/Record | Test reports, laboratory personnel competence |

| Document/Record | Internal Laboratory Scope | |

| 7.1.5.3.2 External laboratory | Document/Record | Laboratory scope |

| Document/Record | External Laboratory Acceptance Checklist | |

| 7.1.6 Organizational Knowledge | Document/Record | Organization knowledge (library, standards, trainings, LMS) |

| Document/Record | Lesson Learned Template | |

| 7.2 Competence | Document/Record | Training records, education, experience record |

| Document/Record | Training Record | |

| Document/Record | Training Program | |

| Mandatory Procedure | Procedure for Competence, Training and Awareness | |

| 7.2.2 Competence — on-the-job training | Document/Record | Operators Job Rotation Matrix |

| Document/Record | On-the-job training records | |

| 7.2.3 Internal auditor competency | Mandatory Procedure | Internal Auditor Competency |

| Document/Record | List of Qualified Internal Auditors | |

| Document/Record | Internal trainer competency records | |

| 7.2.4 Second-party auditor competency | ||

| 7.3 Awareness | Document/Record | Record of Attendance |

| Document/Record | Awareness Training Report | |

| Document/Record | Employee awareness (control plan, FMEA, work instruction) | |

| 7.3.2 Employee motivation and empowerment | Mandatory Procedure | Employee Motivation |

| 7.4 Communication | ||

| 7.5 Documented Information | Mandatory Procedure | Document and Record Control |

| Document/Record | Master list of documents and records | |

| Document/Record | List of absolute and archive documents and records | |

| 7.5.1,1 Quality management system documentation | Document/Record | Quality Manual |

| 7.5.2 Creating And Updating | ||

| 7.5.3 Control Of Documented Information | ||

| 7.5.3.2.1 Record retention | Document/Record | Record retention policy |

| Document/Record | Sample inspection reports, test records | |

| 7.5.3.2.2 Engineering specifications | Mandatory Procedure | Engineering Specification |

| Document/Record | Engineering change records | |

| 8 Operation | ||

| 8.1 Operational Planning And Control | Document/Record | Patrol inspection records, pre-dispatch inspection record |

| 8.1.2 Confidentiality | ||

| 8.2 Requirements For Products And Services | ||

| 8.2.1 Customer Communication | Procedure | Sales Procedure |

| Document/Record | Customer complaints register | |

| 8.2.2 Determining The Requirements For Products And Services | Document/Record | Customer Requirement Review Checklist |

| 8.2.3 Review Of The Requirements For Products And Services | ||

| 8.2.3.1 Review of the requirements for products and services | Document/Record | Feasibility Study Report |

| Document/Record | Customer deviation | |

| 8.2.3.1.2 Customer-designated special characteristics | Document/Record | Customer designated special characteristics |

| 8.2.3.1.3 Organization manufacturing feasibility | Document/Record | Contract review |

| 8.2.4 Changes To Requirements For Products And Services | Document/Record | Process / engineering change records |

| 8.3 Design And Development Of Products And Services | Mandatory Procedure | Procedure for Design and Development |

| 8.3.2 Design And Development Planning | Document/Record | Design review records |

| Document/Record | Project Plan and Review | |

| 8.3.2.2 Product design skills | ||

| 8.3.2.3 Development of products with embedded software | Document/Record | software development capability self-assessment record |

| 8.3.3 Design And Development Inputs | Document/Record | Design review records |

| 8.3.3.1 Product design input | Document/Record | Design review records |

| 8.3.3.2 Manufacturing process design input | Document/Record | Manufacturing process input review |

| 8.3.3.3 Special characteristics | Mandatory Procedure | Special characteristics |

| Document/Record | List of special characteristics | |

| 8.3.4 Design And Development Controls | Document/Record | Design review, verification & validation records |

| 8.3.4.1 Monitoring | ||

| 8.3.4.2 Design and development validation | ||

| 8.3.4.3 Prototype program | ||

| 8.3.4.4 Product approval process | Procedure | Production Part Approval Process Procedure |

| Document/Record | Part submission warrant / product approval record | |

| Document/Record | PPAP Record | |

| 8.3.5 Design And Development Outputs | Document/Record | Design Review Minutes |

| Document/Record | Design review records | |

| 8.3.5.2 Manufacturing process design output | Document/Record | Manufacturing process output review |

| 8.3.6 Design And Development Changes | Document/Record | Change Review Record |

| Document/Record | Engineering change records | |

| Document/Record | Customer deviation, revision level of hardware / software in change records (for embedded software only) | |

| 8.4 Control Of Externally Provided Processes, Products And Services | Procedure | Purchasing and Evaluation of Suppliers |

| Document/Record | Supplier complaint register | |

| Document/Record | Supplier audit / evaluation report | |

| 8.4.1 General | Document/Record | List of Approved Suppliers |

| Document/Record | Request and Order for Purchasing | |

| 8.4.1.2 Supplier selection process | Mandatory Procedure | Supplier Selection |

| Document/Record | Checklist for Evaluation of Suppliers | |

| 8.4.1.3 Customer-directed sources | Document/Record | |

| 8.4.2 Type And Extent Of Control | Document/Record | Incoming Inspection Control Plan and Log |

| Mandatory Procedure | Outsource Process Control procedure | |

| 8.4.2.2 Statutory and regulatory requirements | Mandatory Procedure | Statutory and Regulatory Requirement of purchased product |

| 8.4.2.3 Supplier quality management system development | Document/Record | Software development capability self-assessment record |

| 8.4.2.3.1 Automotive product-related software or automotive products with embedded software | ||

| 8.4.2.4 Supplier monitoring | Mandatory Procedure | Supplier Monitoring |

| Procedure | second-party audits | |

| 8.4.2.4,1 Second-party audits | Document/Record | Second Party Audit Checklist |

| Document/Record | Second-party audit report | |

| 8.4.2.5 Supplier development | ||

| 8.4.3 Information For External Providers | ||

| 8.5 Production And Service Provision | Procedure | Production and Service Provision |

| Document/Record | Quality Plan | |

| 8.5.1 Control Of Production And Service Provision | ||

| 8.5.1.1 Control plan | Document/Record | Control plan |

| 8.5.1.2 Standardized work | Document/Record | Work Instructions |

| 8.5.1.3 Verification of job set-ups | Document/Record | First Part Approval Form |

| Last Part inspection Report | ||

| Document/Record | Job setup records | |

| 8.5.1.4 Verification after shutdown | ||

| 8.5.1.5 Total productive maintenance | Procedure | Equipment Maintenance |

| Document/Record | Maintenance objectives | |

| Document/Record | TQM documents and records | |

| Document/Record | MTBF and MTTR Downtime | |

| Document/Record | Machine Poka yoke list List | |

| Document/Record | Maintenance Work Instruction | |

| 8.5.1.6 Management of production tooling and manufacturing, test, inspection tooling and equipment | Procedure | Tooling Management |

| 8.5.1.7 Production scheduling | Document/Record | Production Scheduling and planning |

| Document/Record | Just-in-time | |

| 8.5.2 Identification And Traceabil1ty | Document/Record | Traceability records (Invoice, Pre-dispatch inspection records, production and quality records) |

| Document/Record | Traceability and identification system | |

| .5.3 Property Belonging To Customers Or External Providers | Document/Record | Notification to a Customer about Changes on their Property |

| Document/Record | Customer property record and status | |

| 8.5.4 Preservation | Document/Record | Inventory management |

| Procedure | Warehousing Procedure | |

| Document/Record | Record of Warehousing Parameters Control | |

| 8.5.5 Post-Delivery Activities | ||

| 8.5.5.1 Feedback of information from service | ||

| 8.5.5.2 Service agreement with customer | ||

| 8.5.6 Control Of Changes | Mandatory Procedure | Control of Changes |

| Document/Record | Process / engineering change records | |

| 8.5.6.1.1 Temporary change of process controls | Document/Record | List of Alternate Controls |

| Mandatory Procedure | Temporary Change of Process Control | |

| Document/Record | list of alternate process control / method | |

| 8.6 Release Of Products And Services | Document/Record | Records of conformity of product and services with acceptance criteria |

| Document/Record | Production Change Review Record Form | |

| 8.6.2 Layout inspection and functional testing | Document/Record | Layout inspection and functional testing records |

| 8.6.3 Appearance items | Document/Record | List of Appearance Items |

| 8.6.4 Verification and acceptance of conformity of externally provided products and services. | Procedure | verification and acceptance of conformity of externally provided products and services |

| Document/Record | Second party auditor report | |

| Document/Record | Third party audit report | |

| 8.6.5 Statutory and regulatory conformity | ||

| 8.6.6 Acceptance criteria | ||

| 8.7 Control Of Nonconforming Outputs | Document/Record | Nonconformity Record |

| 8.7.1.1 Customer authorization for concession | Document/Record | Deviation Request and Approval Form |

| Document/Record | Customer deviation | |

| Document/Record | Internal Failures Report | |

| 8.7.1.2 Control of nonconforming product — customer-specified process | ||

| 8.7.1.3 Control of suspect product | ||

| 8.7.1.4 Control of reworked product | Mandatory Procedure | Control of Rework |

| Document/Record | Rework Instruction | |

| Document/Record | Control plan / drawings, work instruction | |

| Document/Record | Rework record | |

| 8.7.1.5 Control of repaired product | Mandatory Procedure | Control of Repair |

| Document/Record | Control Plan, work instruction | |

| Document/Record | Customer deviation | |

| Document/Record | Repair record | |

| Document/Record | Repair Instruction | |

| 8.7.1.6 Customer notification | Document/Record | Customer notification |

| 8.7.1.7 Nonconforming product disposition | Mandatory Procedure | Non-Conforming Product Handling |

| 8.7.2 | Document/Record | Nonconformity records with action plan |

| 9 Performance Evaluation | ||

| 9.1 Monitoring, Measurement, Analysis And Evaluation | ||

| 9.1.1.1 Monitoring and measurement of manufacturing processes | Document/Record | SPC study, process change records |

| 9.1.1.2 Identification of statistical tools | ||

| 9.1.1.3 Application of statistical concepts | ||

| 9.1.2 Customer Satisfaction | Procedure | customer satisfaction monitoring |

| Document/Record | Customer Satisfaction Dashboard | |

| Document/Record | Customer Satisfaction Questionnaire | |

| Document/Record | Report of Customer Satisfaction | |

| Document/Record | Monitoring of Customer Satisfaction | |

| 9.1.3 Analysis and evaluation | Document/Record | Key Performance Indicators Matrix |

| Document/Record | Data Analysis Report | |

| 9.1.3,1 Prioritization | ||

| 9.2 Internal Audit | Document/Record | Internal audit scope and criteria |

| Document/Record | Plan Vs Actual | |

| Document/Record | Internal Audit Report for QMS Audits | |

| 9.2.2.1 internal audit program | Procedure | Internal Audit |

| Document/Record | Internal QMS Audit Checklist | |

| 9.2.2.2 Quality management system audit | Document/Record | Internal Audit Program |

| 9.2.2.3 Manufacturing process audit | Document/Record | Manufacturing Process Audit Checklist |

| 9.2.2.4 Product audit | Document/Record | Product Audit Checklist/report |

| Dock Audit Checklist/report | ||

| 9.3 Management review | Procedure | Management review |

| 9.3.2 Management Review Inputs | ||

| 9.3.3 Management Review Outputs | Document/Record | Management review minutes of meeting |

| Document/Record | Action plan when customer performance targets not met | |

| 10 Improvement | ||

| 10.2 Nonconformity And Corrective Action | Document/Record | Nonconformity records with action plan |

| Document/Record | Registry and Status of Nonconformities and Corrective Actions | |

| 10.2.3 Problem solving | Mandatory Procedure | Corrective Action/ Problem-Solving |

| Document/Record | Problem Solving 8D Report | |

| Document/Record | Control Plan, FMEA | |

| 10.2.4 Error-proofing | Mandatory Procedure | Poka Yoke/ Error Proofing |

| 10.2.5 Warranty management systems | Document/Record | Report of Warranty Failures |

| Document/Record | Warranty Incidents Analysis Report | |

| Document/Record | Product User Instruction Template | |

| Procedure | warranty management process | |

| 10.2.6 Customer complaints and field failure test analysis | ||

| 10.3 Continual Improvement | Mandatory Procedure | Continual Improvement |

Hope this complete list of QMS documentation will give you the idea of how every organization has the documents and what is the requirement behind it.

This quality management system document structure is followed worldwide by every organization who want to eligible for IATF certification.