Hello all, in this article we learn about the Pareto analysis.

What is Pareto Principle?

This was originally used by Vilfredo Pareto, who was a 19th century Italian professor of political economy. This Italian Economist observe that the 20% of any country’s population have more or less 80% of country’s total income. This observation then known as Pareto’s principle.

Now why is this applicable for us?

The Pareto analysis is used in situations to help prioritize the top contributor from many source of opportunities. For example, Which project’s to be select first from several projects or find out top defect to act from many defect categories.

A Pareto analysis allows you to focus on the most frequently occurring defect types. It helps you to decide which defect types to eliminate first. And as I just said the method is based on a distribution proposed by the Italian professor Wilfredo Pareto. To describe the principle helps in prioritizing the “vital few” from “useful many” based on their potential benefits. This 80-20 rule was then used during the second world war, in fact the term was coined by Dr. Juran who extended this principle to quality control. He stated for instance that most defects in production are the result of a small percentage of the causes of all the defects.

Now other examples we may have for this 80-20 principles are for example

- 1- 80% of customer complaint from 20% of customers.

- 2- 80% of defective quantity due to 20% of defects.

- 3- 80% of your company’s profit due to 20% of your product’s.

If we are taking the problem to eliminate which is not effective for the company, then after the successful completion we will not achieve big results, Therefor the idea of pareto diagram is to select the important problem among the various problem which leads to good result.

Now the problem is how to select the important one…

- Base on the number of times the problem repeated / frequency of occurrence

- Even though the problem is repeated with high frequency but base on the cost other problem is creating more loss to the company, so select according to this scenario if like this.

- Likewise, some problem is less repeating but affect the safety.

Once we collect the data, based on this using the stratification we select the biggest one by using the pareto analysis.

Let’s take an example,

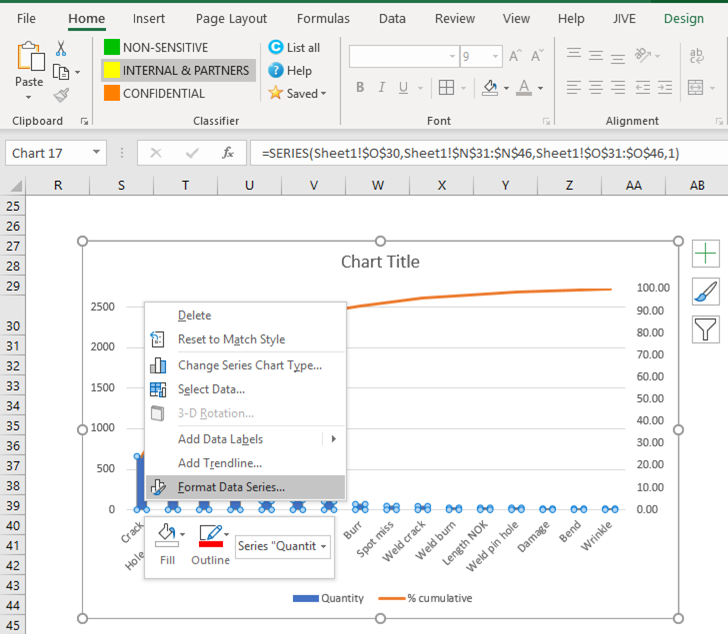

1. We have the defect wise data for Tube assembly, as shown in the chart below

2. Arrange / Sort the data in largest to smallest number

3. Calculate the cumulative and % cumulative quantity in the chart

4. Select the columns of Defect, Quantity & % Cumulative, and insert the chart as shown in step below

Use combo chart

5. Now click on the cumulative line, right click and click on format data series & select the secondary axis option

6. Click on right side scale of cum. % then right click & then click format Axis and put values minimum as 0 & maximum as 100%.

7. Similarly select the left scale and put the values minimum as 0 & maximum as total quantity 2725.

8. Click on the bars to select them and right click, then select format data series and make gap zero.

9. Now you have the actual pareto chart, still final tuning is require… then you will get the final pareto chart as below.

- Add data label to cumulative line

- Write the specific chart title to represent the pareto chart

The Pareto analysis consists of obtaining data on the frequency at which the different defect’s have been occurring in recent history. We want to rank then, the defect’s based on their frequency with a defect having the highest frequency being ranked first. And then a diagram, the Pareto diagram, is made with a percentage frequency on the y-axis and the defect’s on the x-axis arranged in largest to smallest order of frequency. So, here we would our Pareto diagram.

Finally, the conclusion from this chart is the 20% of the defect category i.e. Crack, Hole undersize, Loose fitment & Hole oversize contribute our 80% of defective quantity (Rejection).

We also want to be able to perform a Pareto analysis by ranking causes and creating a Pareto diagram. Let’s just look again at our six sigma road map on our problem-solving strategy used in six sigma. Here we have

y = f(x),

where y = representing the critical to quality parameters that the customer values.

X = influencers, the parameters that influence or affect the y’s.

And now in our DMAIC cycle what we want to do is to list down all possible x to the very few, that having main impact on Y. This all done in analyse phase of six sigma. We’ll have a cause and effect analysis where we’re identifying critical x’s and then we’re establishing their influence on the y’s. Using for example designed experiments, correlation regression. And in this section we want to focus on how we can reduce all to the very few using a Pareto analysis.

I am a full time Engineer and Quality Professional with over 11+ years of experience in the automotive industry. My professional journey has started from a small enterprise quality inspector to a advanced quality expert. I am creating a good-quality content for engineers. Help them to grow in their career.Learn more here.