Introduction – What is a Check Sheet and Why It Matters #

In manufacturing and automotive industries, decisions must be based on facts and data, not assumptions. and how do we collect data?

For this purpose Check Sheet is one of the simplest and most powerful data-collection tool.

It is the first tool in among 7 QC Tools.

This helps quality engineers to systematically collect data of process performance, defect occurrences, or inspection results.

It is a structured, easy-to-use form used directly on the shop floor to record the frequency or pattern of specific events.

Think of this as your first step in problem-solving, before you draw a Pareto chart or Fishbone diagram, you need accurate data, and that’s where a check sheet provide you that data.

Concept Explanation – Understanding the Check Sheet #

It is a data recording format designed to capture specific information consistently and quickly. It ensures that everyone collects data in the same format, avoiding confusion and subjective judgment.

Key Characteristics of a Check Sheet:

- Simple and easy to use on the shop floor

- Focused on a specific defect, event, or activity

- Standardized layout for clear and consistent recording

- Enables quick tally and visual analysis

Purpose of a Check Sheet: #

- To record how often a particular defect or event occurs

- Tool for collecting, organizing, and record measured or counted data.

- To identify patterns and trends over time

- To provide a factual base for analysis using tools like Pareto Chart or Fishbone Diagram

- Tool for collecting, organizing, and record measured or counted data.

- Collected data is used for analysis using other quality tools. Input data for other quality tools.

What are the types of Check Sheets? #

- Process distribution

- Defective cause-wise

- Defect location

- Defective cause

1] Process Distribution Check Sheet #

This type of checksheet is design in such a way that we can get the process distribution while recording data. This type of checklist will help to understand the product or process behavior.

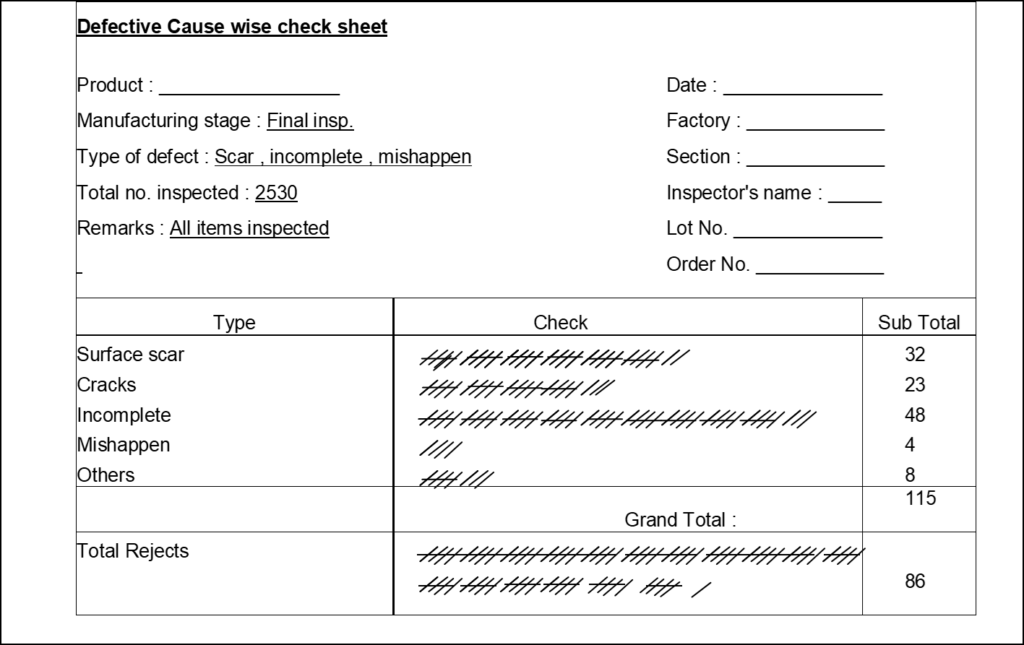

2] Defect Cause-wide Check Sheet #

This type of check-sheet is use to count the defects data. The data is counted based on how many times one cause or type of defect is produced. This data shows the behavior of defects and count.

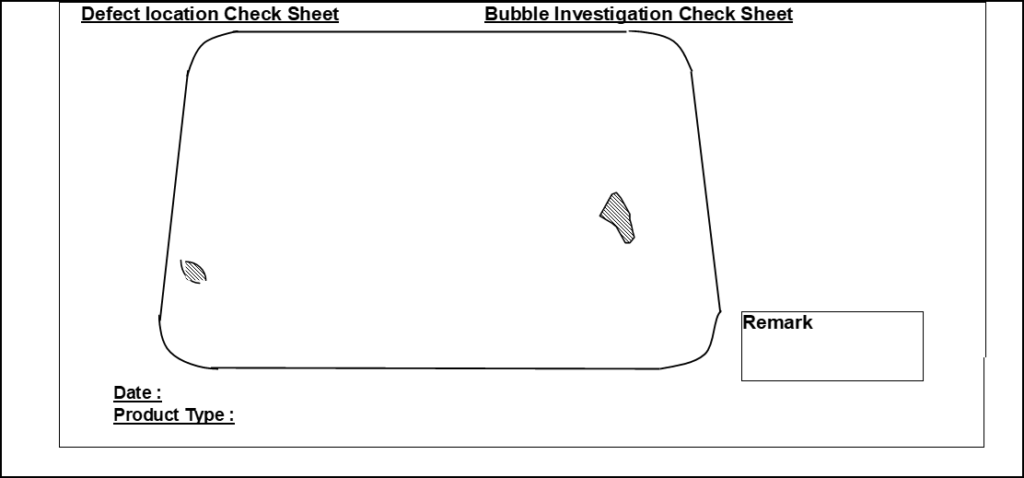

3] Defect location Check-Sheet #

As the name itself gives us the idea that it represents the location of the defect. To collect the data on which exactly the defect occurs on the part, this type of check-sheet will help.

This checksheet represents the location behavior of the defects.

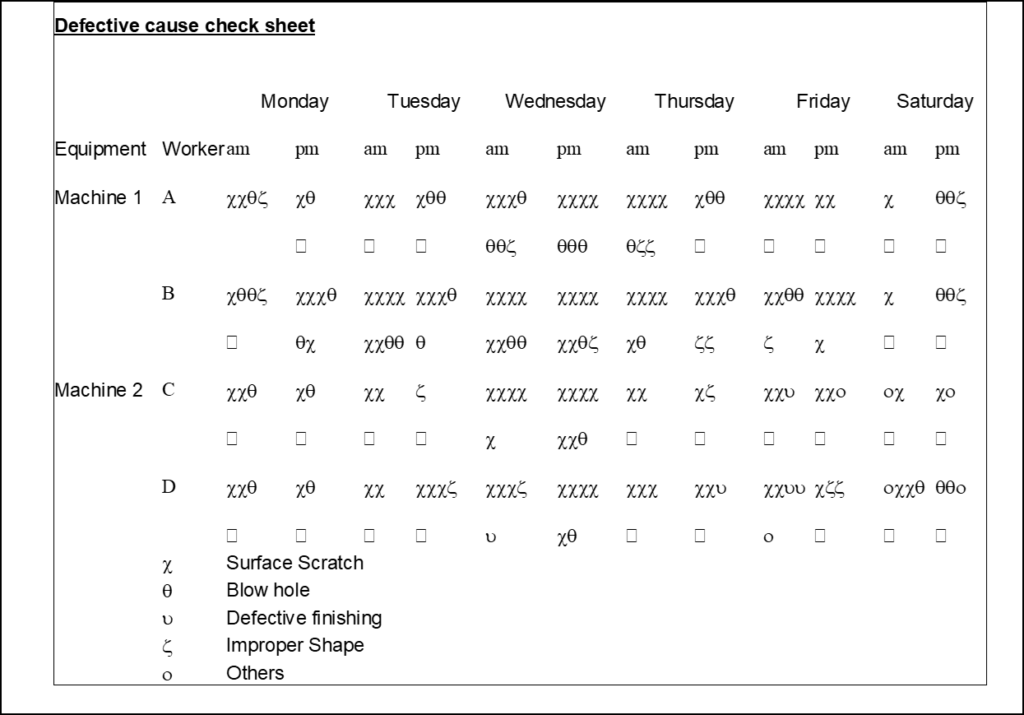

4] Defect Cause Check Sheet #

To check the detailed defect and cause relation this checksheet will help.

Here we can add multiple symbols for the different defects and record them to check the behavior on a different machine. Or You can use it for different operators also to collect the data of defects.

This type of checksheet will represent the cause and defect relationship.

Step-by-Step: How to Create / Use a Check Sheet #

Follow these six simple steps to create and use a CheckSheet effectively:

Step 1: Define the Purpose

Decide what you want to measure, e.g., number of defects, machine downtime, or rejected parts. A clear focus avoids collecting unnecessary data.

Step 2: Decide the Type of Data

Choose what you’ll record:

- Frequency of defects

- Location of defects on a product

- Cause or time of occurrence

- Type of defect by process or shift

Step 3: Design the Sheet Format

Create a simple form with:

- Date and shift

- Product name or ID

- Defect types or events to record

- Columns for tally marks or counts

- Name of inspector/operator

| Date | Shift | Product | Defect Type | Tally | Total |

|---|---|---|---|---|---|

| 12-Oct-2025 | A | Brake Pedal | Welding Issue | || | 2 |

| 12-Oct-2025 | A | Brake Pedal | Paint Defect | 卌 | 5 |

| 12-Oct-2025 | A | Brake Pedal | Assembly Error | ||| | 3 |

Step 4: Collect the Data

Use tally marks each time a defect or event occurs. Keep the sheet at the workstation where data can be recorded in real time.

Step 5: Review and Summarize

At the end of the shift or day, count tallies and record totals. This helps identify which issues occur most often.

Step 6: Analyze the Data

Convert the totals into percentages or graphs (like a Pareto chart) to prioritize key problems.

Practical Example – Check Sheet in Automotive Manufacturing #

Imagine you work in a welding line for car door frames.

Operators record defects for one week using a this sheet.

| Defect Type | Frequency (Tally) | Total |

|---|---|---|

| Spatter | 卌卌 | 10 |

| Porosity | 卌 卌 卌 | 15 |

| Poor penetration | 卌 卌 卌 卌 卌 | 25 |

| Misalignment | 卌 | 5 |

| Cracks | ||| | 3 |

Interpretation:

- Out of 58 total defects, poor penetration is the top issue (43%).

- You can now draw a Pareto chart to focus on the major causes, aligning with the 80/20 rule.

Advantages and Limitations #

Advantages #

- Easy to design and use on shop floors

- Provides factual, real-time data

- Helps visualize frequency and trends

- Forms the foundation for Pareto, Histogram, or Cause-and-Effect analysis

Limitations #

- Only as accurate as the data recorded

- May not capture the “why” behind the problem (requires other tools)

- Manual entry can lead to human errors if not standardized

Best Practices & Tips of using check sheet #

- Train operators on how to mark data consistently.

- Use clear defect names or codes to avoid confusion.

- Place the check sheet at the point of inspection.

- Review data daily or weekly to identify patterns early.

- Digitalized check sheets using Excel or tablets for faster analysis.

Common Mistakes & How to Avoid Them #

| Mistake | How to Avoid |

|---|---|

| Collecting too many data points | Focus on a specific problem or product |

| Ambiguous defect categories | Use standard defect definitions |

| Missing operator/shift info | Include header information in every sheet |

| Inconsistent tallying | Train team and verify periodically |

| Not reviewing data | Schedule daily review sessions |

Download Check Sheet Template #

Check Sheet → Pareto Chart → Fishbone Diagram → 5 Why Analysis.

Summary / Key Takeaways #

- A Check Sheet is the foundation of all 7 QC Tools.

- It helps collect accurate, consistent, and actionable data.

- Real-time usage on the shop floor ensures better analysis later.

- Once data is collected, it can be easily converted into Pareto charts or used in Root Cause Analysis.

Start small, choose one process, design a simple check sheet, and use it daily. Soon you’ll see data-driven improvement becoming part of your team’s culture.

Frequently Asked Questions (FAQ) #

To collect data in a structured and consistent way to identify frequency or patterns of defects or events.

No, it can also track events, delays, downtime, or inspection results.

A check sheet records data or frequency; a checklist ensures tasks are completed.

Yes, digital check sheets in Excel or apps make analysis faster and reduce human errors.

You can analyze the data using Pareto Chart, Histogram, or Fishbone Diagram to find root causes.

Download the free Check Sheet template and start collecting real data from your process today.

Then, move on to the next tool, [Pareto Chart – Practical Guide in Detail] to analyze your findings.