To do any analysis, the data is been measured and collected using the form. So this form is called a check Sheet quality tool. It is a structured way of collecting the information.

So we measured and collect data for analysis. This activity is planning in such a way that the information data collected is relevant and complete.

Therefore the check sheets are one of the 7 quality tools for collecting data. They are design and use specifically for the type of data to be record or collected. Check sheets help in the systematic collection of data.

Some examples of check sheets are daily maintenance check sheets, attendance records, production log books, etc.

Purpose of Check Sheet

- Tool for collecting, organizing, and record measured or counted data.

- Collected data is used for analysis using other quality tools. Input data for other quality tools.

What are the types of Check Sheets?

- Process distribution check sheet

- Defective cause-wise check sheet

- Defect location check sheet

- Defective cause check sheet

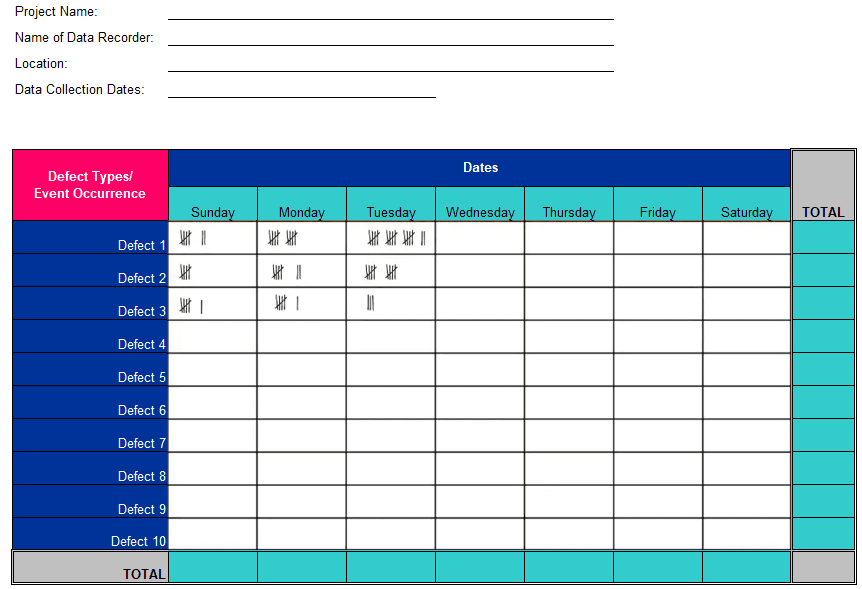

1] Process Distribution Check Sheet

This type of checksheet is design in such a way that we can get the process distribution while recording data. This type of checklist will help to understand the product or process behavior.

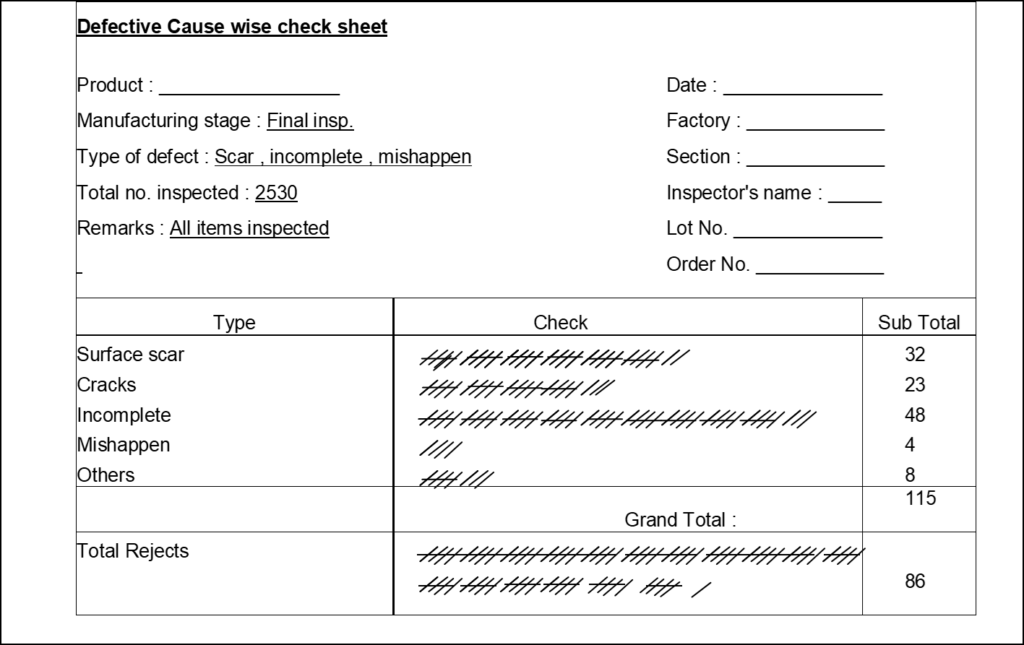

2] Defect Cause-wide Check Sheet

This type of check sheet is use to count the defects data. The data is counted based on how many times one cause or type of defect is produced. This data shows the behavior of defects and count.

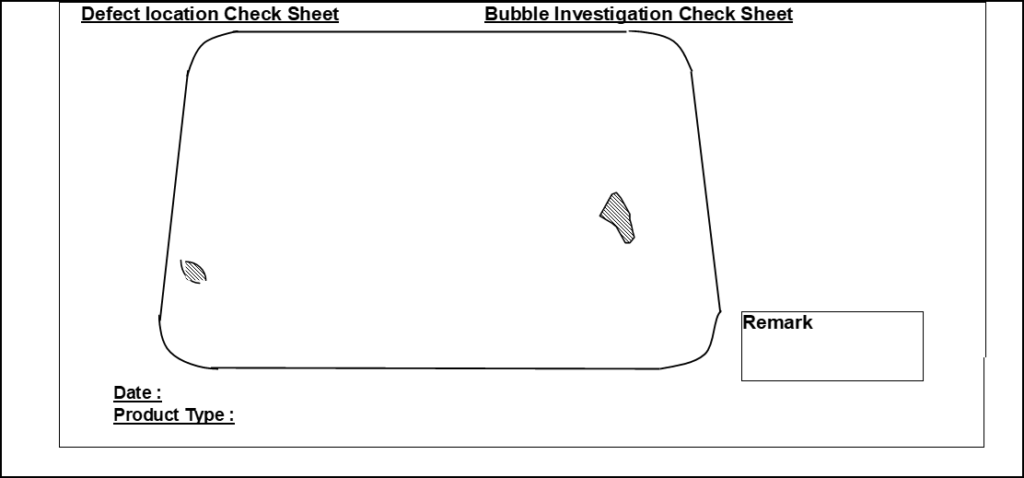

3] Defect location Check Sheet

As the name itself gives us the idea that it represents the location of the defect. To collect the data on which exactly the defect occurs on the part, this type of check sheet will help.

This check sheet represents the location behavior of the defects.

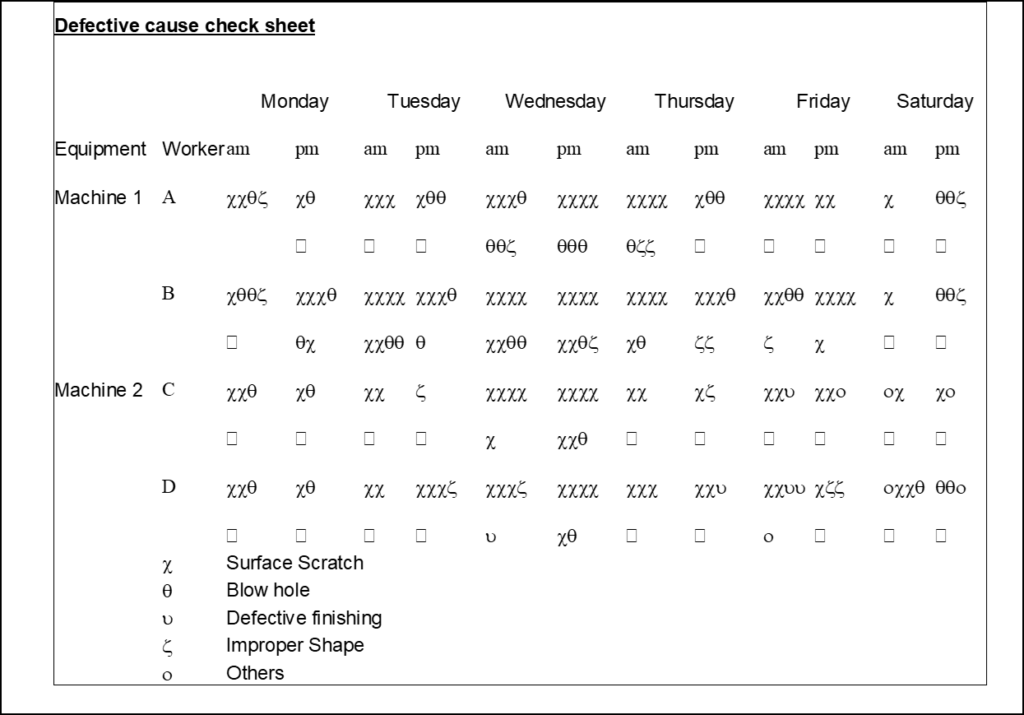

4] Defect Cause Check Sheet

To check the detailed defect and cause relation this check sheet will help.

Here we can add multiple symbols for the different defects and record them to check the behavior on a different machine. Or You can use it for different operators also to collect the data of defects.

This type of checksheet will represent the cause and defect relationship.

Benefits of Check Sheet

- Collect data in a systematic and organized manner

- To determine the source of the problem

- To facilitate the classification of data (stratification)

- Check sheet Quality tool